- -€12.50

Shop

-

Turning

add remove

-

TURNING INSERTS

-

- Negative turning inserts

- Positive turning inserts

- CBN-Inserts

- PCD-Inserts

-

PARTING AND GROOVING

-

- Outside grooving

- Inside grooving

- Axial grooving

- Grooving Inserts

-

- Milling add remove

-

Drilling

add remove

-

TIP DRILLS

-

- Drill Bases

- Drill Tips

-

INDEXEABLE INSERT DRILLS

-

- SPMG Drills

- WCMX Drills

- Compatible indexable insert drills

- Multi-Cut

- Drill inserts

-

SOLID CARBIDE DRILLS

-

- Solid carbide NC spotting drill

- Solid Carbide Drills

- Step Drills

-

-

-

Compatible Tools

add remove

-

COMPATIBLE INSERTS

-

- Compatible Grooving Inserts

- Compatible Milling Inserts

- Compatible Drilling Inserts

-

- Sets

-

Spare Parts and Accessories

add remove

-

SPARE PARTS & ACCESSORIES

-

- Shims and accessories

- Knee levers and accessories

- Claws and accessories

- Insert Screws

- Torque-Screwdrivers

-

- SPECIAL OFFERS

- Sample Inserts

- Catalogs

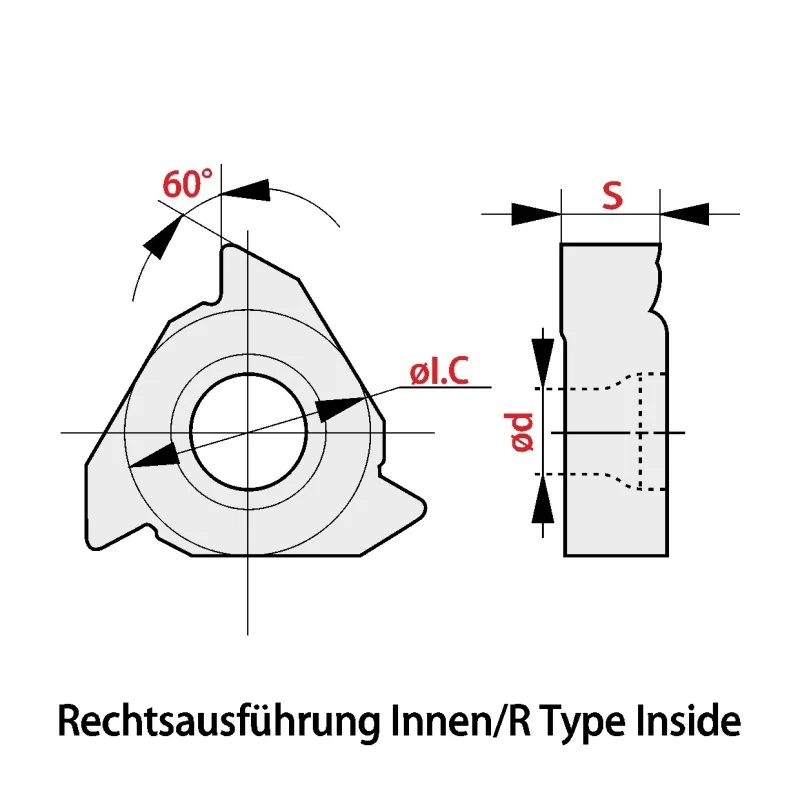

Threading insert Sets - 5x SAME 16IR...-G RT315 (60°) with pitch of your Choice

| Insert size | 16 |

| Inside/Outside Thread | Inside |

| Direction | Right |

| Thread Type | Metric |

| Profile | Full profile |

| Workpiece Materials | Steel, Stainless Steel, Special Materials, NF-Metals |

| Flank angle | 60° |

| Grade | RT315: PVD-coated P15-P25 and M10-M25 for universal use |

| Packaging Unit | 5 pc. |

In the “Threading Inserts” category you will find thread cutting inserts with chip formers

in different versions (BSPT, UNC, etc.).

| ISO | Pitch | I.C | S | d | |

| 5 x 16IR-V-ISO-1,0 RT315 | 16 | 1,0 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-1,25 RT315 |

16 | 1,25 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-1,5 RT315 |

16 | 1,5 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-1,75 RT315 |

16 | 1,75 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-2,0 RT315 |

16 | 2,0 mm | 9,525 | 3,52 | 4 |

| Insert size | 16 |

| Inside/Outside Thread | Inside |

| Direction | Right |

| Thread Type | Metric |

| Profile | Full profile |

| Workpiece Materials | Steel, Stainless Steel, Special Materials, NF-Metals |

| Flank angle | 60° |

| Grade | RT315: PVD-coated P15-P25 and M10-M25 for universal use |

| Packaging Unit | 5 pc. |

In the “Threading Inserts” category you will find thread cutting inserts with chip formers

in different versions (BSPT, UNC, etc.).

| Item Nr. | ISO | Pitch | I.C | S | d | |

| 2 x 16IR-V-ISO-1,0-G RT315 | 9991701 | 16 | 1,0 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-1,25-G RT315 |

9991702 | 16 | 1,25 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-1,5-G RT315 |

9991703 | 16 | 1,5 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-1,75-G RT315 |

9991704 | 16 | 1,75 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-2,0-G RT315 |

9991705 | 16 | 2,0 mm | 9,525 | 3,52 | 4 |

| ISO | Material | Cutting Data |

| P | Steel | Vc= 80-150 m/min |

| M | Stainless Steel | Vc= 80-120 m/min |

| N | NF-Metals | Vc= 120-300 m/min |

| S | Special Materials | Vc= 20-60 m/min |

Data sheet

- Inside/Outside

- Inside

- Gewindeplatten Große

- 16

- Gewindeplatten Verwendung

- RT315 Steel and Stainless Steel

- Gewinde

- Metric

- Materials

- NF-Metals

Plastic

Special Materials

Stainless Steel

Steel - Rechts-Links

- Right

- thread profile

- Full profile

| Insert size | 16 |

| Inside/Outside Thread | Inside |

| Direction | Right |

| Thread Type | Metric |

| Profile | Full profile |

| Workpiece Materials | Steel, Stainless Steel, Special Materials, NF-Metals |

| Flank angle | 60° |

| Grade | RT315: PVD-coated P15-P25 and M10-M25 for universal use |

| Packaging Unit | 5 pc. |

In the “Threading Inserts” category you will find thread cutting inserts with chip formers

in different versions (BSPT, UNC, etc.).

| ISO | Pitch | I.C | S | d | |

| 5 x 16IR-V-ISO-1,0 RT315 | 16 | 1,0 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-1,25 RT315 |

16 | 1,25 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-1,5 RT315 |

16 | 1,5 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-1,75 RT315 |

16 | 1,75 mm | 9,525 | 3,52 | 4 |

| 5 x 16IR-V-ISO-2,0 RT315 |

16 | 2,0 mm | 9,525 | 3,52 | 4 |

Compatible products

Internal Threading Tool Holder - SIR Right - with cooling holes

| Boring Bar | SIR |

| Insert | 11/16/22 IR |

| Right/Left | Right |

| Main application | Threading |

| Clamping | Screw Clamp |

| Cooling | With Cooling Hole |

| Packaging Unit | 1 Pc. |

| d | b | L | h | f | L1 | Dmin | |

| SIR-16 K11-H | 16 | 15,5 | 125 | 15 | 10 | 20,9 | 12 |

| SIR-16 M11-H | 16 | 16 | 150 | 15 | 10,5 | 25,9 | 16 |

| SIR-16 M16-H | 16 | 15,5 | 150 | 15 | 12 | 27 | 20 |

| SIR-20 M16-H | 20 | 19 | 150 | 18 | 14 | 28,7 | 25 |

| SIR-20 Q16-H | 20 | 19 | 180 | 18 | 14 | 34 | 25 |

| SIR-25 M16-H | 25 | 24 | 150 | 23 | 17 | 28,8 | 32 |

| SIR-32 R16-H | 32 | 31 | 200 | 30 | 22 | 30,9 | 40 |

| SIR-32 S16-H | 32 | 31 | 250 | 30 | 22 | 30,9 | 40 |

| SIR-40 T16-H | 40 | 38,5 | 300 | 37 | 27 | 31,5 | 50 |

| SIR-20 Q22-H | 20 | 19 | 180 | 18 | 15 | 35 | 25 |

| SIR-25 R22-H | 25 | 24 | 200 | 23 | 19 | 39 | 32 |

| SIR-32 S22-H | 32 | 31 | 250 | 30 | 22 | 36,4 | 40 |

| SIR-40 T22-H | 40 | 38,5 | 300 | 37 | 27 | 37,2 | 50 |

Internal Threading Tool Holder - SIR Right

| Boring Bar | SIR |

| Insert | 11/16/22 IR |

| Right/Left | Right |

| Main application | Threading |

| Clamping | Screw Clamp |

| Cooling | Without Cooling Holes |

| Packaging Unit | 1 Pc. |

| d | b | L | h | f | L1 | Dmin | |

| SIR-10 K11 | 10 | 10 | 125 | 9 | 7 | - | 12 |

| SIR-12 K11 | 12 | 12 | 125 | 11 | 10 | - | 16 |

| SIR-16x13 M16 | 16 | 13 | 150 | 15 | 10 | 32 | 16 |

| SIR-16 M16 | 16 | 15,5 | 150 | 15 | 12 | 27 | 20 |

| SIR-20 M16 | 20 | 19 | 150 | 18 | 14 | 28,7 | 25 |

| SIR-20 Q16 | 20 | 19 | 180 | 18 | 14 | 34 | 25 |

| SIR-25 M16 | 25 | 24 | 150 | 23 | 17 | 28,8 | 32 |

| SIR-32 R16 | 32 | 31 | 200 | 30 | 22 | 30,9 | 40 |

| SIR-32 S16 | 32 | 31 | 250 | 30 | 22 | 30,9 | 40 |

| SIR-40 T16 | 40 | 38,5 | 300 | 37 | 27 | 31,5 | 50 |

| SIR-50 U16 | 50 | 49,5 | 350 | 49 | 35 | 40,2 | 63 |

| SIR-20 Q22 | 20 | 19 | 180 | 18 | 15 | 35 | 25 |

| SIR-25 R22 | 25 | 24 | 200 | 23 | 19 | 39 | 32 |

| SIR-32 S22 | 32 | 31 | 250 | 30 | 22 | 36,4 | 40 |

| SIR-40 T22 | 40 | 38,5 | 300 | 37 | 27 | 37,2 | 50 |

| SIR-50 U22 | 50 | 48,5 | 350 | 47 | 35 | 42,6 | 63 |

10 other products in the same category:

SPECIAL OFFER!! High Feed Modular Mill - HEF-SD.. Set

SDMT High Feed Modular Mill Set

consisting of:

1x SDMT High Feed Modular Mill of your choice

10x Milling Inserts of your choice

Available High Feed Modular Mills:

| ØD | Ød | L | M | Z | ap max | Insert | |

| HEF-SD09-D25-M12-L35-Z02-H | 25 | 24 | 35 | 12 | 2 | 1,4 | SDMT 09T3.. |

| HEF-SD09-D30-M16-L45-Z03-H | 30 | 29 | 45 | 16 | 3 | 1,4 | SDMT 09T3.. |

| HEF-SD09-D32-M16-L45-Z04-H | 32 | 30 | 45 | 16 | 4 | 1,4 | SDMT 09T3.. |

| HEF-SD09-D35-M16-L45-Z04-H | 35 | 30 | 45 | 16 | 4 | 1,4 | SDMT 09T3.. |

| HEF-SD09-D40-M16-L45-Z04-H | 40 | 30 | 45 | 16 | 4 | 1,4 | SDMT 09T3.. |

Available Milling Inserts:

|

Grade

|

RT253: CVD-coated M20–M35 carbide grade for roughing operations in stainless steel |

|

RT250X: PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

|

|

RT300: PVD-coated P15–P25 and M10–M25 carbide grade for universal applications in steel and stainless steel |

|

|

RT820S: CVD-coated S10–S20 / M15–M35 high-performance milling grade for difficult-to-machine materials such as special alloys (titanium, Inconel, Hastelloy, and stainless steels such as 1.4571) |

| L | I.C | S | d | r | |

| SDMT 09T312–NM RT250X | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT253 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–PM RT300 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT820S | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

SPECIAL OFFER!! SMCR/L XC.. MULTI CUT Set

Multi Cut Set

consisting of:

1x Multi Cut of your choice

5x Inserts XCMT...-EN RT300

| Tool Typ | Multifunction Tool |

| Angle | 90° |

| Applications | Longitudinal turning - Facing- Drilling |

| Insert | XC.. |

| Packaging Unit | 1 Pc. |

Diameter of your Choice:

| d | d1 | d2 | L1 | L2 | L3 | F | |

| SMCR/L 10x2,5 XC..05... | 10 | 12 | 16 | 25 | 32 | 42 | 5 |

| SMCR/L 12x2,5 XC..06... |

12 | 16 | 20 | 30 | 40 | 45 | 6 |

| SMCR/L 16x2,5 XC..08... |

16 | 20 | 25 | 40 | 53 | 50 | 8 |

| SMCR/L 20x2,5 XC..10... |

20 | 25 | 34 | 50 | 66 | 55 | 10 |

Matching indexable inserts – automatically selected and included:

| Plate Shape | XCMT |

| Workpiece Material | Steel, Stainless Steel |

| Grade | RT300 = PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel |

| Packaging unit | 5 Pc. |

| L | d | S | r | Ød1 | |

| XCMT 050204-EN RT300 | 5,0 | 5,4 | 2,10 | 0,4 | 2,3 |

| XCMT 060204-EN RT300 | 6,0 | 6,4 | 2,38 | 0,4 | 2,5 |

| XCMT 080304-EN RT300 | 8,0 | 8,4 | 3,18 | 0,4 | 3,4 |

| XCMT 10T308-EN RT300 | 10,0 | 10,4 | 3,97 | 0,4 | 4,0 |

Solid Carbide Roughing Mill

| Mill Type | Solid Carbide Roughing Mill |

| Helix Angle | 30° |

| Workpiece Material | Steel, Stainless Steel, Cast Iron |

| Processing | Roughing |

| Shank | Weldon Shank |

| Grade | RT405: PVD-TIALN-coated high-performance grade for solid carbide milling cutters |

| Packaging unit | 1 Pc |

- Centre Cutting

| D | d(h5) | H | L | Z | |

| SFR-Z3-D6.0 RT405 | 6 | 6 | 16 | 57 | 3 |

| SFR-Z3-D8.0 RT405 | 8 | 8 | 16 | 63 | 3 |

| SFR-Z4-D10.0 RT405 | 10 | 10 | 22 | 72 | 4 |

| SFR-Z4-D12.0 RT405 | 12 | 12 | 26 | 83 | 4 |

| SFR-Z4-D14.0 RT405 | 14 | 14 | 26 | 83 | 4 |

| SFR-Z4-D16.0 RT405 | 16 | 16 | 32 | 92 | 4 |

| SFR-Z4-D18.0 RT405 | 18 | 18 | 32 | 92 | 4 |

| SFR-Z4-D20.0 RT405 | 20 | 20 | 38 | 104 | 4 |

| SFR-Z4-D25.0 RT405 | 25 | 25 | 45 | 121 | 5 |

End Mill APKT 11 Set

APKT11 End Mill Set

consisting of:

1x APKT11 End Mill of your choice

10x Milling Inserts of your choice

Available End Mills:

| D | d | Z | L | M | ap max | |

| EF90-AP11-D16-M10-L28-Z02 | 16 | 15,2 | 2 | 28 | 10 | 10,5 |

| EF90-AP11-D20-M12-L30-Z02 | 20 | 19 | 2 | 30 | 12 | 10,5 |

| EF90-AP11-D25-M14-L35-Z03 | 25 | 24 | 3 | 35 | 14 | 10,5 |

| EF90-AP11-D32-M16-L43-Z05 | 32 | 29 | 5 | 43 | 16 | 10,5 |

Available Milling Inserts:

|

Grades |

RT250X: PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

| RT250: CVD-coated K10-K20 carbide for rough cast machining | |

| RT100: Uncoated K10-K15 carbide for ALU and plastics | |

| RT305H: PVD-coated high-performance grade for a wide range of applications. |

| L | d | s | I.W | r | |

| APKT 11T304-PF RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T312-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 1,2 |

| APKT 11T316-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

| APKT 11T320-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 2,0 |

| APKT 11T3-HV RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | - |

| APKT 11T304-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T312-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 1,2 |

| APKT 11T316-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

| APKT 11T320-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 2,0 |

| APKT 11T304-ALZ RT100 🟢 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-ALZ RT100 🟢 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T308-PM RT305H 🔵🟡🟠 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T316-PM RT305H 🔵🟡🟠 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

SPECIAL OFFER!! High Feed Mill - MK-HV-SD.. Set

SDMT Shoulder Mill Set

consisting of:

1x SDMT Shoulder Mill of your choice

10x Milling Inserts of your choice

Available Shoulder-Mills:

| ØD | ød | ap | L | Z | Coupling | Insert | |

| MK-HV-SD09-D40-A16-Z04-H | 40 | 16 | 1,4 | 40 | 4 | A | SDMT 09T3.. |

| MK-HV-SD09-D50-A22-Z05-H | 50 | 22 | 1,4 | 40 | 5 | A | SDMT 09T3.. |

| MK-HV-SD09-D63-A22-Z06-H | 63 | 22 | 1,4 | 40 | 6 | A | SDMT 09T3.. |

| ØD | ød | ap | L | Z | Coupling | Insert | |

| MK-HV-SD12-D50-A22-Z04-H | 50 | 22 | 1,8 | 40 | 4 | A | SDMT 1204.. |

| MK-HV-SD12-D52-A22-Z04-H | 52 | 22 | 1,8 | 40 | 4 | A | SDMT 1204.. |

| MK-HV-SD12-D63-A22-Z05-H | 63 | 22 | 1,8 | 40 | 5 | A | SDMT 1204.. |

| MK-HV-SD12-D66-A27-Z05-H | 66 | 27 | 1,8 | 50 | 5 | A | SDMT 1204.. |

| MK-HV-SD12-D80-A27-Z07-H | 80 | 27 | 1,8 | 50 | 7 | A | SDMT 1204.. |

| MK-HV-SD12-D100-B32-Z07-H | 100 | 32 | 1,8 | 50 | 7 | B | SDMT 1204.. |

| MK-HV-SD12-D125-B40-Z09 | 125 | 40 | 1,8 | 63 | 9 | B | SDMT 1204.. |

Available Milling Inserts:

|

Grade

|

RT253: CVD-coated M20–M35 carbide grade for roughing operations in stainless steel |

|

RT250X: PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

|

|

RT300: PVD-coated P15–P25 and M10–M25 carbide grade for universal applications in steel and stainless steel |

|

|

RT820S: CVD-coated S10–S20 / M15–M35 high-performance milling grade for difficult-to-machine materials such as special alloys (titanium, Inconel, Hastelloy, and stainless steels such as 1.4571) |

| L | I.C | S | d | r | |

| SDMT 09T312–NM RT250X | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT253 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–PM RT300 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT820S | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 120412–NM RT250X | 12,7 | 12,7 | 4,76 | 4,4 | 1,2 |

| SDMT 120412–PM RT300 | 12,7 | 12,7 | 4,76 | 4,4 | 1,2 |

Modular Mill APKT 11 Set

APKT11 Modular Mill Set

consisting of:

1x APKT11 Modular Mill of your choice

10x Milling Inserts of your choice

Available Modular Mills:

| D | d | Z | L | M | ap max | |

| EF90-AP11-D16-M08-L25-Z02 | 16 | 12,5 | 2 | 25 | 8 | 10,5 |

| EF90-AP11-D20-M10-L30-Z03 | 20 | 18 | 3 | 30 | 10 | 10,5 |

| EF90-AP11-D25-M12-L35-Z04 | 25 | 21 | 4 | 35 | 12 | 10,5 |

| EF90-AP11-D32-M16-L43-Z05 | 32 | 29 | 5 | 43 | 16 | 10,5 |

Available Milling Inserts:

|

Grades |

RT250X: PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

| RT250: CVD-coated K10-K20 carbide for rough cast machining | |

| RT100: Uncoated K10-K15 carbide for ALU and plastics | |

| RT305H: PVD-coated high-performance grade for a wide range of applications. |

| L | d | s | I.W | r | |

| APKT 11T304-PF RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T312-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 1,2 |

| APKT 11T316-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

| APKT 11T320-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 2,0 |

| APKT 11T3-HV RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | - |

| APKT 11T304-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T312-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 1,2 |

| APKT 11T316-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

| APKT 11T320-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 2,0 |

| APKT 11T304-ALZ RT100 🟢 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-ALZ RT100 🟢 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T308-PM RT305H 🔵🟡🟠 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T316-PM RT305H 🔵🟡🟠 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

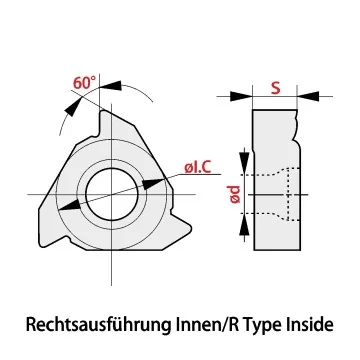

Threading insert Sets - 16IR...-G RT315 (60°) metric full profile

| Insert size | 16 |

| Inside/Outside Thread | Inside |

| Direction | Right |

| Thread Type | Metric |

| Profile | Full profile |

| Workpiece Materials | Steel, Stainless Steel, Special Materials, NF-Metals |

| Flank angle | 60° |

| Grade | RT315 = PVD-coated P15-P25 and M10-M25 for universal use |

| Packaging Unit | 2 pc. |

In the “Threading Inserts” category you will find thread cutting inserts with chip formers

in different versions (BSPT, UNC, etc.).

The set consists of 10 thread cutting plates with chip former: ::

| ISO | Pitch | I.C | S | d | |

| 2 x 16IR-V-ISO-1,0 RT315 | 16 | 1,0 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-1,25 RT315 |

16 | 1,25 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-1,5 RT315 |

16 | 1,5 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-1,75 RT315 |

16 | 1,75 mm | 9,525 | 3,52 | 4 |

| 2 x 16IR-V-ISO-2,0 RT315 |

16 | 2,0 mm | 9,525 | 3,52 | 4 |

SPECIAL OFFER!! High Feed Mill - HSF-SD.. Set

SDMT Shoulder Mill Set

consisting of:

1x SDMT Shoulder Mill of your choice

10x Milling Inserts of your choice

Available Shoulder-Mills:

| D | d | L1 | L | Z | ap max | Insert | |

| HSF-SD09-D25-W25-L140-Z02-H | 25 | 25 | 60 | 140 | 2 | 1,4 | SDMT 09... |

| HSF-SD09-D32-W32-L150-Z03-H | 32 | 32 | 70 | 150 | 3 | 1,4 | SDMT 09... |

| HSF-SD09-D35-W32-L150-Z03 | 35 | 32 | 70 | 150 | 3 | 1,4 | SDMT 09... |

Available Milling Inserts:

|

Grade

|

RT253: CVD-coated M20–M35 carbide grade for roughing operations in stainless steel |

|

RT250X: PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

|

|

RT300: PVD-coated P15–P25 and M10–M25 carbide grade for universal applications in steel and stainless steel |

|

|

RT820S: CVD-coated S10–S20 / M15–M35 high-performance milling grade for difficult-to-machine materials such as special alloys (titanium, Inconel, Hastelloy, and stainless steels such as 1.4571) |

| L | I.C | S | d | r | |

| SDMT 09T312–NM RT250X | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT253 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–PM RT300 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT820S | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

Solid Carbide HPC Mill Set 6 - 12 mm

| Mill Typ | Solid Carbide End mill Set |

| Spiral Angle | 35°/38° |

| Material | Steel, Stainless Steel, Cast Iron |

| Processing | Roughing and Finish |

| Length | Standard Lenght |

| Shaft | Weldon Shaft |

| Teeth | 4 |

| Coating | RT405: PVD-TiAlN-coated high-performance grade for solid carbide milling cutters |

| Packaging unit | 1 Pc |

- 4 flute solid carbide cutter

- Cutting across the middle

- TiAlN-coated

- Roughing/finishing

- consisting of respectively 1x 6/8/10/12 mm

- Unevenly divided spiral for roughing, finishing and neck relief (M)

| d(h6) | d1 | H | M | L | Z | |

| 6 | 6 | 5,7 | 13 | 21 | 57 | 4 |

| 8 | 8 | 7,7 | 19 | 27 | 63 | 4 |

| 10 | 10 | 9,5 | 22 | 32 | 72 | 4 |

| 12 | 12 | 11,5 | 26 | 38 | 83 | 4 |

Shoulder Mill APKT 11 Set

APKT11 Shoulder Mill Set

consisting of:

1x APKT11 Shoulder Mill of your choice

10x Milling Inserts of your choice

Available Shoulder-Mills:

| D | Z | d | L | ap max | |

| MK90-AP11-D040-A16 Z05-H | 40 | 5 | 16 | 40 | 10,5 |

| MK90-AP11-D050-A22 Z06-H | 50 | 6 | 22 | 40 | 10,5 |

| MK90-AP11-D063-A22 Z08-H | 63 | 8 | 22 | 40 | 10,5 |

Available Milling Inserts:

|

Grades |

RT250X = PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

| RT250K = CVD-coated K10-K20 carbide for rough cast machining | |

| RT100 = Uncoated K10-K15 carbide for ALU and plastics | |

| RT305H: PVD-coated high-performance grade for a wide range of applications. |

| L | d | s | I.W | r | |

| APKT 11T304-PF RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T312-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 1,2 |

| APKT 11T316-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

| APKT 11T320-PM RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | 2,0 |

| APKT 11T3-HV RT250X 🔵🟡 | 12,24 | 2,8 | 3,6 | 6,5 | - |

| APKT 11T304-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T312-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 1,2 |

| APKT 11T316-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |

| APKT 11T320-PM RT150K 🔴 | 12,24 | 2,8 | 3,6 | 6,5 | 2,0 |

| APKT 11T304-ALZ RT100 🟢 | 12,24 | 2,8 | 3,6 | 6,5 | 0,4 |

| APKT 11T308-ALZ RT100 🟢 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T308-PM RT305H 🔵🟡🟠 | 12,24 | 2,8 | 3,6 | 6,5 | 0,8 |

| APKT 11T316-PM RT305H 🔵🟡🟠 | 12,24 | 2,8 | 3,6 | 6,5 | 1,6 |