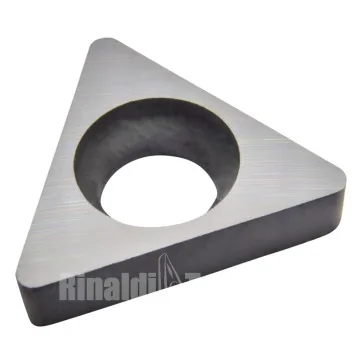

3-flute VBH drill 3xD - cylindrical shank with cooling holes

High-speed drilling in steel and cast iron with a feed rate of 1.5 to 2 times that of conventional drills.

Self-centering and improved chip breaking through R thinning.

RT19 = CVD-coated P25/K20 carbide grade for universal drilling of steel and cast materials.

Packaging unit = 1 Pc.

| Drill Diameter | Shaft Diameter | Spiral lenght | Overall Lenght |

| D1 | d2 | L1 | L2 |

| 5 mm | 6 | 44 | 82 |

| 5,1 mm | 6 | 44 | 82 |

| 5,2 mm | 6 | 44 | 82 |

| 5,3 mm | 6 | 44 | 82 |

| 5,4 mm | 6 | 44 | 82 |

| 5,5 mm | 6 | 44 | 82 |

| 5,6 mm | 6 | 44 | 82 |

| 5,7 mm | 6 | 44 | 82 |

| 5,8 mm | 6 | 44 | 82 |

| 5,9 mm | 6 | 44 | 82 |

| 6 mm | 6 | 44 | 82 |

| 6,1 mm | 8 | 53 | 91 |

| 6,2 mm | 8 | 53 | 91 |

| 6,3 mm | 8 | 53 | 91 |

| 6,4 mm | 8 | 53 | 91 |

| 6,5 mm | 8 | 53 | 91 |

| 6,6 mm | 8 | 53 | 91 |

| 6,7 mm | 8 | 53 | 91 |

| 6,8 mm | 8 | 53 | 91 |

| 6,9 mm | 8 | 53 | 91 |

| 7 mm | 8 | 53 | 91 |

| 7,1 mm | 8 | 53 | 91 |

| 7,2 mm | 8 | 53 | 91 |

| 7,3 mm | 8 | 53 | 91 |

| 7,4 mm | 8 | 53 | 91 |

| 7,5 mm | 8 | 53 | 91 |

| 7,6 mm | 8 | 53 | 91 |

| 7,7 mm | 8 | 53 | 91 |

| 7,8 mm | 8 | 53 | 91 |

| 7,9 mm | 8 | 53 | 91 |

| 8 mm | 8 | 53 | 91 |

| 8,1 mm | 10 | 61 | 103 |

| 8,2 mm | 10 | 61 | 103 |

| 8,3 mm | 10 | 61 | 103 |

| 8,4 mm | 10 | 61 | 103 |

| 8,5 mm | 10 | 61 | 103 |

| 8,6 mm | 10 | 61 | 103 |

| 8,7 mm | 10 | 61 | 103 |

| 8,8 mm | 10 | 61 | 103 |

| 8,9 mm | 10 | 61 | 103 |

| 9 mm | 10 | 61 | 103 |

| 9,1 mm | 10 | 61 | 103 |

| 9,2 mm | 10 | 61 | 103 |

| 9,3 mm | 10 | 61 | 103 |

| 9,4 mm | 10 | 61 | 103 |

| 9,5 mm | 10 | 61 | 103 |

| 9,6 mm | 10 | 61 | 103 |

| 9,7 mm | 10 | 61 | 103 |

| 9,8 mm | 10 | 61 | 103 |

| 9,9 mm | 10 | 61 | 103 |

| 10 mm | 10 | 61 | 103 |

| 10,1 mm | 12 | 71 | 118 |

| 10,2 mm | 12 | 71 | 118 |

| 10,3 mm | 12 | 71 | 118 |

| 10,4 mm | 12 | 71 | 118 |

| 10,5 mm | 12 | 71 | 118 |

| 10,6 mm | 12 | 71 | 118 |

| 10,7 mm | 12 | 71 | 118 |

| 10,8 mm | 12 | 71 | 118 |

| 10,9 mm | 12 | 71 | 118 |

| 11 mm | 12 | 71 | 118 |

| 11,1 mm | 12 | 71 | 118 |

| 11,2 mm | 12 | 71 | 118 |

| 11,3 mm | 12 | 71 | 118 |

| 11,4 mm | 12 | 71 | 118 |

| 11,5 mm | 12 | 71 | 118 |

| 11,6 mm | 12 | 71 | 118 |

| 11,7 mm | 12 | 71 | 118 |

| 11,8 mm | 12 | 71 | 118 |

| 11,9 mm | 12 | 71 | 118 |

| 12 mm | 12 | 71 | 118 |

| 12,5 mm | 14 | 77 | 124 |

| 13 mm | 14 | 77 | 124 |

| 13,5 mm | 14 | 77 | 124 |

| 14 mm | 14 | 77 | 124 |

| 14,5 mm | 16 | 83 | 133 |

| 15 mm | 16 | 83 | 133 |

| 15,5 mm | 16 | 83 | 133 |

| 16 mm | 16 | 83 | 133 |

| 16,5 mm | 18 | 93 | 143 |

| 17 mm | 18 | 93 | 143 |

| 17,5 mm | 18 | 93 | 143 |

| 18 mm | 18 | 93 | 143 |

| 18,5 mm | 20 | 101 | 153 |

| 19 mm | 20 | 101 | 153 |

| 19,5 mm | 20 | 101 | 153 |

| 20 mm | 20 | 101 | 153 |