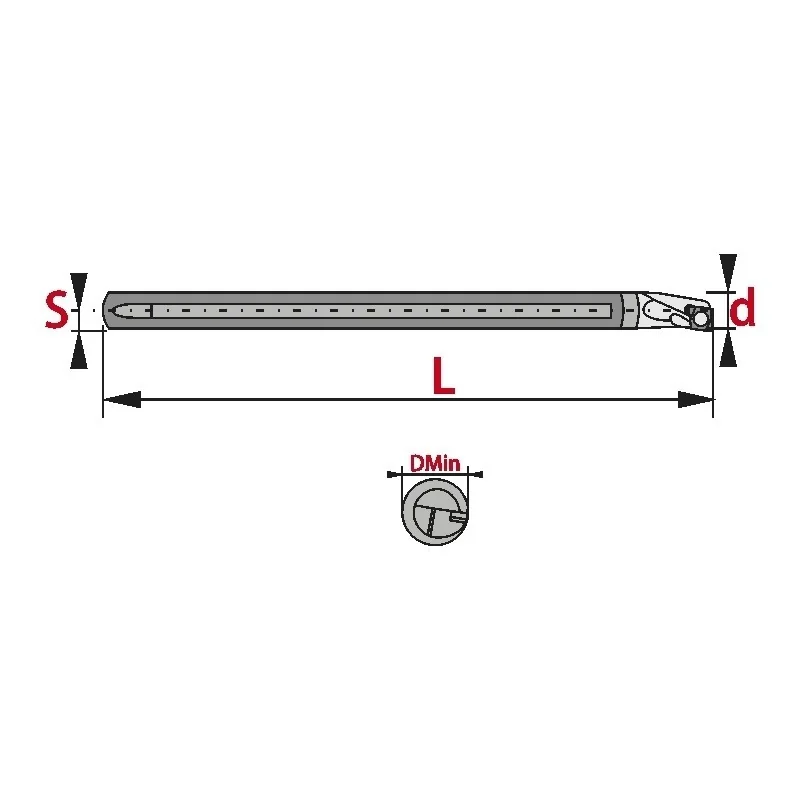

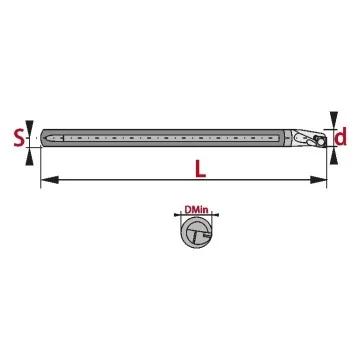

Sleeve

Price

ab €27.00

Availability: 214748357 In Stock

Packaging unit = 1 Pc.

| Ød | a | b | c | ØD | H | L | |

| SL1604 (For E04...Boring bars) | 4 | 5 | 6 | -- | 16 | 14 | 100 |

| SL1605 (For E05...Boring bars) | 5 | 5 | 8 | -- | 16 | 14 | 100 |

| SL1606 (For E06...Boring bars) | 6 | 5 | 6 | 6 | 16 | 14 | 100 |