Solid Carbide Ball Nose Cutter - Extra Long Shank - Prisma-Line

| Mill Type | Solid Carbide Ball Nose Cutter |

| Helix Angle | 30° |

| Workpiece Material | Steel, Stainless Steel, Cast Iron |

| Processing | Finish |

| Lenght | Extra Long Shank |

| Shank | Cylindrical Shank |

| Flutes | 2 |

| Grade | RT303: PVD-coated fine-grain carbide for general Application in milling (VHM) |

| Packaging unit | 1 Pc |

- 2-Flute Solid Carbide Ball Nose Cutter

- Centre Cutting

- PVD-Coated

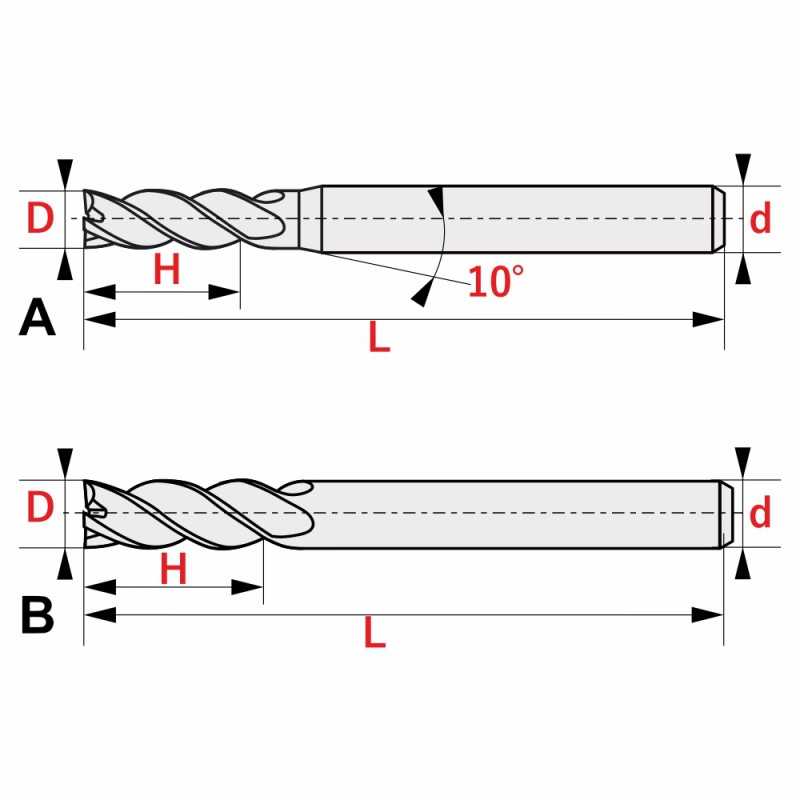

| D | r | d(h6) | H | L | Z | |

| KFEL-P-Z2-D6.0 RT303 | 6 | 3 | 6 | 12 | 100 | 2 |

| KFEL-P-Z2-D8.0 RT303 | 8 | 4 | 8 | 16 | 100 | 2 |

| KFEL-P-Z2-D10.0 RT303 | 10 | 5 | 10 | 20 | 150 | 2 |

| KFEL-P-Z2-D12.0 RT303 | 12 | 6 | 12 | 24 | 150 | 2 |