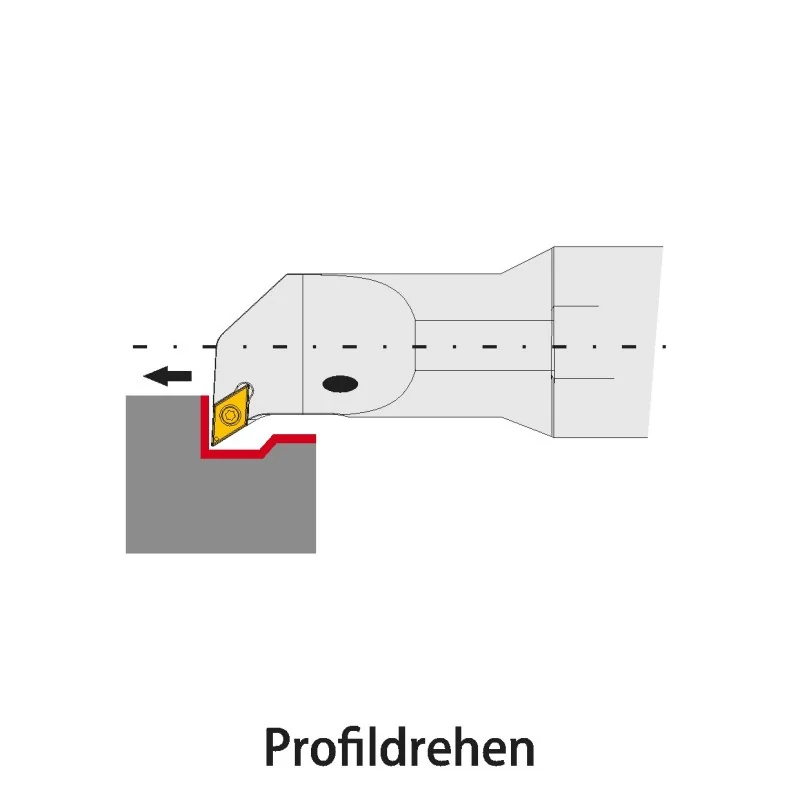

A-SCLCR/L(95°) Set Inside turning holders with cooling holes

Art. Nr. Right: SM60050

Art. Nr. Left: SM60067

consisting of:

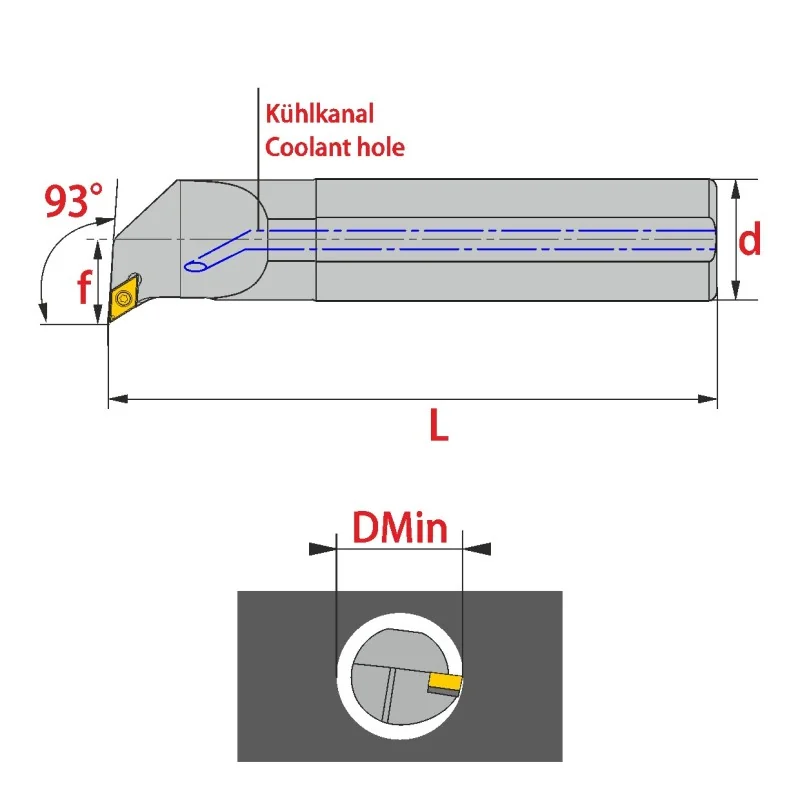

| d | H | L | f | Dmin | |

| A08H SCLCR/L 06 with cooling holes | 8 | 7 | 100 | 07 | ≥11 |

| A10H SCLCR/L 06 with cooling holes | 10 | 9 | 100 | 08 | ≥13 |

| A12H SCLCR/L 06 with cooling holes | 12 | 11 | 100 | 10 | ≥16 |

| A16M SCLCR/L 09 with cooling holes | 16 | 15 | 150 | 13 | ≥21 |

Packaging Unit = 1 Pc.