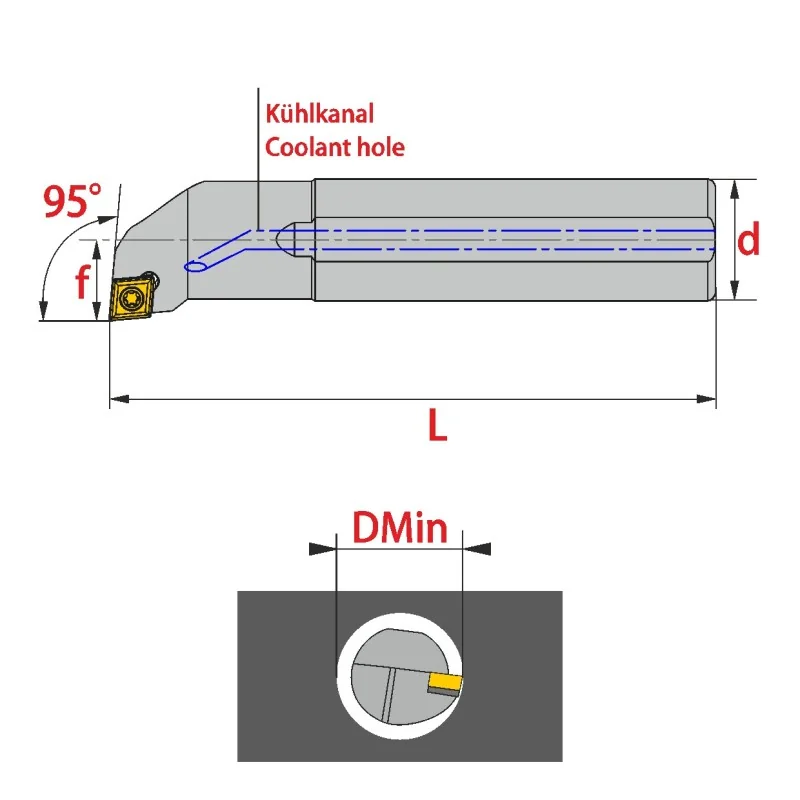

E-SDUCR/L (93°)-Set Solid Carbide Inside turning holders with cooling holes

| Boring Bar Set | E-SDUCR/L |

| Setting Angle | 93° |

| Insert | DC.. |

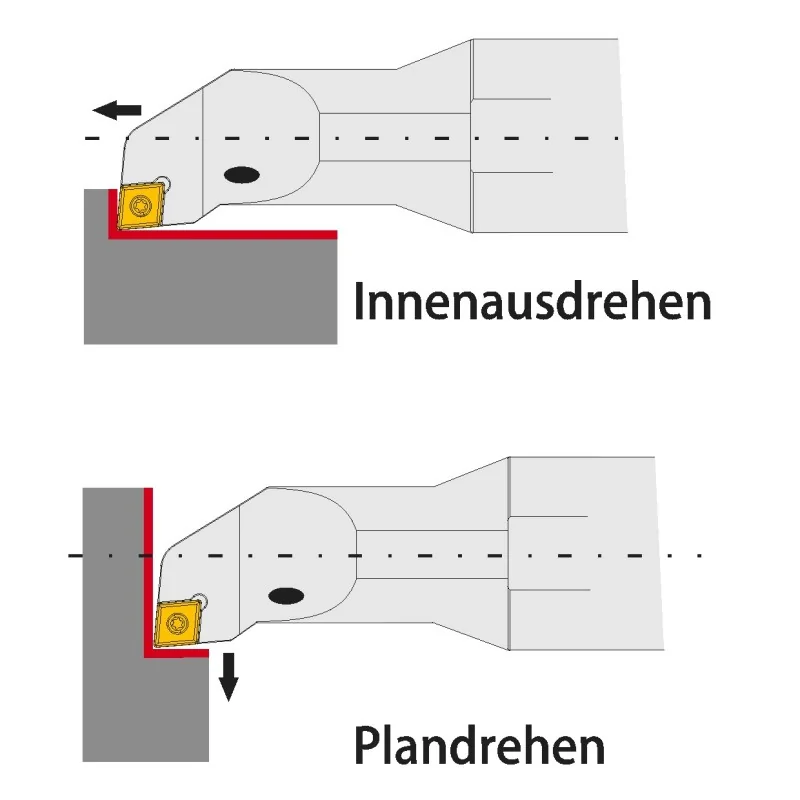

| Main application | Profile turning |

| Clamping | Screw Clamp |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

Solid carbide boring bar

Solid carbide tool carriers increase stability considerably.

The carbide boring bar allows a projection length of up to 6xD by reducing vibrations.

Precision and surface quality are also improved.

Art. Nr. Right: SM59870

Art. Nr. Left: SM59887

consisting of:

| d | L | f | Dmin | |

| E10M SDUCR/L-07 mit IK | 10 | 150 | 08 | ≥13 |

| E12Q SDUCR/L-07 mit IK | 12 | 180 | 10 | ≥16 |

| E16R SDUCR/L-11 mit IK | 16 | 200 | 13 | ≥21 |