TURNING INSERTS

PARTING AND GROOVING

TIP DRILLS

INDEXEABLE INSERT DRILLS

SOLID CARBIDE DRILLS

COMPATIBLE INSERTS

SPARE PARTS & ACCESSORIES

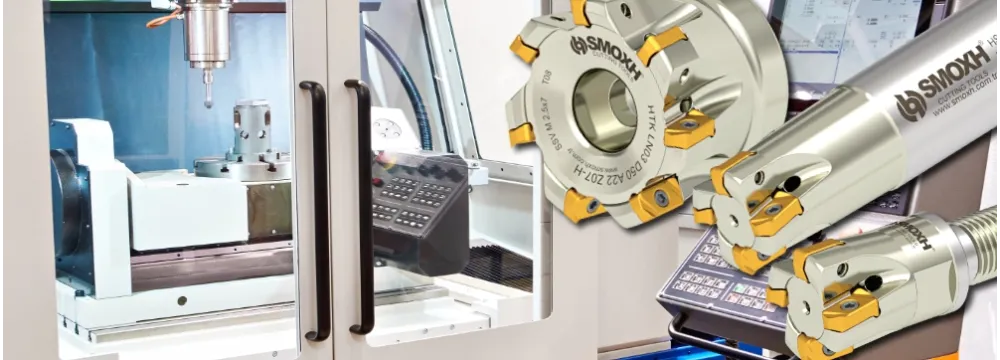

High-feed milling has developed into one of the most important technologies in modern machining over recent years. This innovative machining process is characterized by the use of extremely high feed rates combined with simultaneously low cutting depths, thereby revolutionizing efficiency in machining operations.

In contrast to conventional milling, where cutting speed is the dominant parameter, high-feed milling focuses on feed rate. Typical feed values range between 0.8 and 4.0 mm per cutting edge, while axial cutting depths are deliberately kept low - usually between 0.2 and 2.0 mm.

The indexable inserts for high-feed milling feature a characteristic geometry: they are significantly more rounded and have a large corner radius or even a completely round shape. This geometry makes it possible to handle the high feed forces while ensuring stable cutting guidance.

High-feed machining produces a special chip form: the chips are significantly thinner than with conventional processes, but wider. These "comma chips" result from the special kinematics of the process and lead to more uniform heat distribution. Heat is primarily dissipated through the chip, which reduces tool load.

The most important advantage of high-feed milling lies in the enormous productivity increase. Through the combination of high feed rates and optimized chip formation, material removal rates can be achieved that are 3 to 8 times those of conventional machining processes. This leads to a significant reduction in machining times and thus to lower unit costs.

Paradoxically, high feed rates do not lead to worse surface qualities, but often to better ones. The continuous cutting action and optimized chip formation reduce vibrations and chatter marks. Surface roughness values of Ra 0.8 to Ra 1.6 μm are achievable as standard, often even without post-processing.

The special geometry of high-feed cutters distributes cutting forces more evenly across the cutting edge. Combined with effective heat dissipation through the chip, this results in lower thermal and mechanical loads on the tool. The result is longer tool life and higher process reliability.

High-feed milling is suitable for a variety of machining operations: roughing, finishing, face milling, pocket milling, and even 3D contour machining. The technology is particularly effective for machining large surfaces and workpieces with complex geometries.

In addition to pure productivity increases, high-feed milling offers further economic advantages: reduced machine costs per workpiece through shorter machining times, lower energy consumption per unit volume, and often the possibility to consolidate machining steps or eliminate downstream operations.

Our LNMX system represents the latest development stage in high-feed milling technology. As a further development for 2025, it combines years of experience in machining technology with innovative design principles and state-of-the-art manufacturing processes.

Optimized Insert Geometry: The LNMX indexable inserts feature a specially developed geometry that offers a perfect balance between cutting performance and tool life. The precisely calculated corner radius and optimized rake face design ensure controlled chip formation even at extreme feed rates.

Advanced Coating Technology: Our 2025 development utilizes an innovative multi-layer PVD coating specifically developed for the requirements of high-feed milling. This coating combines high wear resistance with excellent sliding properties and extends tool life by up to 40% compared to conventional coatings.

The LNMX system is optimized for a wide range of materials:

Our LNMX system has been consistently designed for economic efficiency and sustainability. The high material removal rate not only reduces machining times but also energy consumption per workpiece. The extended tool life reduces tool consumption and thus environmental impact.

Already in the development and testing phase, the LNMX cutters showed impressive results: productivity increases of 200-500% compared to conventional cutters, tool life of over 90 minutes in high-performance machining, and consistent surface qualities even with extreme parameters.

High-feed milling is more than just a trend - it is the future of efficient machining. Our LNMX system brings this technology to a new level and offers our customers the opportunity to significantly increase their productivity while improving machining quality.

The 2025 further development of our LNMX cutters in our shop represents the current state of technology and offers a future-proof investment in the efficiency of your production. Discover the advantages of high-feed milling with our innovative LNMX system and revolutionize your machining processes.

Visit our shop and experience the future of machining with our LNMX high-feed milling system - developed for 2025, ready for your challenges.

| Mill typ | High Feed Mill |

| Insert | LNMX 0303 |

| Packaging unit | 1 Pc. |

| D | d | L | a | Z | Insert | |

| HTK LN03 D40 A16 Z05-H | 40 | 16 | 40 | 1 | 5 | LNMX 0303 |

| HTK LN03 D42 A16 Z05-H | 42 | 16 | 40 | 1 | 5 | LNMX 0303 |

| HTK LN03 D50 A22 Z07-H | 50 | 22 | 40 | 1 | 7 | LNMX 0303 |

| HTK LN03 D52 A22 Z07-H | 52 | 22 | 40 | 1 | 7 | LNMX 0303 |

| Mill typ | High Feed Mill |

| Insert | LNMX 0303 |

| Packaging unit | 1 Pc. |

| D | d | L | l | Z | |

| HST LN03 D16 W16 L150 Z02-H | 16 | 16 | 150 | 40 | 2 |

| HST LN03 D20 W20 L150 Z03-H | 20 | 20 | 150 | 40 | 3 |

| HST LN03 D25 W25 L150 Z04-H | 25 | 25 | 150 | 40 | 4 |

| HST LN03 D32 W32 L150 Z05-H | 32 | 32 | 150 | 40 | 5 |

| Mill type | High Feed Mill |

| Insert | LNMX 0303 |

| Packaging unit | 1 Pc. |

| D | Z | d1 | d2 | L | l | M | ap max | |

| MHT LN03 D16 M08 L25 Z02-H | 16 | 2 | 15 | 8,5 | 25 | 17 | 8 | 1 |

| MHT LN03 D20 M10 L30 Z03-H | 20 | 3 | 18 | 10,5 | 30 | 19 | 10 | 1 |

| MHT LN03 D25 M12 L35 Z04-H | 25 | 4 | 21 | 12,5 | 35 | 23 | 12 | 1 |

| MHT LN03 D32 M16 L43 Z05-H | 32 | 5 | 29 | 17 | 43 | 23 | 16 | 1 |

| MHT LN03 D35 M16 L43 Z05-H | 35 | 5 | 29 | 17 | 43 | 23 | 16 | 1 |

| MHT LN03 D40 M16 L43 Z06-H | 40 | 6 | 29 | 17 | 43 | 23 | 16 | 1 |

| MHT LN03 D42 M16 L43 Z06-H | 42 | 6 | 29 | 17 | 43 | 23 | 16 | 1 |

| Shape | LNMX |

| Processing | High Feed |

| Workpiece Material | Steel and Stainless Steel |

| Grade |

RT300: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel |

|

RT330: PVD-coated P15-P25 and M10-M25 with additional TiN-coating for improved wear-detection |

|

| Packaging unit | 10 Pc. |

.

| L | apmax | W | S | r | |

| LNMX 0303-MU RT300 | 11,86 | 1,00 | 6 | 4,29 | 1,20 |

| LNMX 0303-MU RT330 New! | 11,86 | 1,00 | 6 | 4,29 | 1,20 |

| Mill type | High Feed Mill |

| Insert | LNMX 0904 |

| Packaging unit | 1 Pc. |

| D | d | L | a | Z | Insert | |

| HTK BL09 D40 A16 Z05-H | 40 | 16 | 40 | 1,5 | 5 | LNMX 0904 |

| HTK BL09 D42 A16 Z05-H | 42 | 16 | 40 | 1,5 | 5 | LNMX 0904 |

| HTK BL09 D50 A22 Z06-H | 50 | 22 | 40 | 1,5 | 6 | LNMX 0904 |

| HTK BL09 D52 A22 Z06-H | 52 | 22 | 40 | 1,5 | 6 | LNMX 0904 |

| HTK BL09 D63 A22 Z07-H | 63 | 22 | 40 | 1,5 | 7 | LNMX 0904 |

| HTK BL09 D66 A27 Z08-H | 66 | 27 | 50 | 1,5 | 8 | LNMX 0904 |

| HTK BL09 D80 A27 Z10-H | 80 | 27 | 50 | 1,5 | 10 | LNMX 0904 |

| HTK BL09 D100 A32 Z12-H | 100 | 32 | 50 | 1,5 | 12 | LNMX 0904 |

| Mill typ | High Feed Mill |

| Insert | LNMX 0904 |

| Packaging unit | 1 Pc. |

| D | d | L | l | Z | ap max | Insert | |

| HST BL09 D25 W25 L150 Z03-H | 25 | 25 | 150 | 40 | 3 | 1,5 | LNMX 0904 |

| HST BL09 D32 W32 L150 Z04-H | 32 | 32 | 150 | 40 | 4 | 1,5 | LNMX 0904 |

| Mill typ | High Feed Mill |

| Insert | LNMX 0904 |

| Packaging unit | 1 Pc. |

| D | Z | d1 | d2 | L | l | M | ap max | |

| MHT BL09 D25 M12 L35 Z03-H | 25 | 3 | 21 | 12,5 | 35 | 23 | 12 | 1,5 |

| MHT BL09 D32 M16 L43 Z04-H | 32 | 4 | 29 | 17 | 43 | 23 | 16 | 1,5 |

| MHT BL09 D35 M16 L43 Z04-H | 35 | 4 | 29 | 17 | 43 | 23 | 16 | 1,5 |

| MHT BL09 D40 M16 L43 Z05-H | 40 | 5 | 29 | 17 | 43 | 23 | 16 | 1,5 |

| Shape | LNMX |

| Processing | High Feed |

| Workpiece Material | Steel and Stainless Steel |

| Grade | RT330: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel |

| Cutting edges | 4 |

| Packaging unit | 10 Pc. |

| L | APmax | W | S | r | |

| LNMX 0904-MU RT330 | 11,94 | 1,50 | 9,2 | 4,79 | 1,20 |

Categories