Shop

-

Turning

add remove

-

TURNING INSERTS

-

- Negative turning inserts

- Positive turning inserts

- CBN-Inserts

- PCD-Inserts

-

PARTING AND GROOVING

-

- Outside grooving

- Inside grooving

- Axial grooving

- Grooving Inserts

-

- Milling add remove

-

Drilling

add remove

-

TIP DRILLS

-

- Drill Bases

- Drill Tips

-

INDEXEABLE INSERT DRILLS

-

- SPMG Drills

- WCMX Drills

- Compatible indexable insert drills

- Multi-Cut

- Drill inserts

-

SOLID CARBIDE DRILLS

-

- Solid carbide NC spotting drill

- Solid Carbide Drills

- Step Drills

-

-

-

Compatible Tools

add remove

-

COMPATIBLE INSERTS

-

- Compatible Grooving Inserts

- Compatible Milling Inserts

- Compatible Drilling Inserts

-

- Sets

-

Spare Parts and Accessories

add remove

-

SPARE PARTS & ACCESSORIES

-

- Shims and accessories

- Knee levers and accessories

- Claws and accessories

- Insert Screws

- Torque-Screwdrivers

-

- SPECIAL OFFERS

- Sample Inserts

- Catalogs

- Home

- About us

-

- Downloads

- Variety description add remove

- FAQ

- Contact us

-

SMOXH

add remove

Turning

add remove

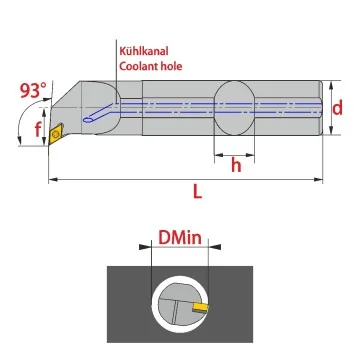

Internal Tool Holder - SDUCR/L (93°) with cooling holes

| Boring Bar | SDUCR/L |

| Cutting Angle | 93° |

| Insert | DC.. |

| Clamping | Screw Clamping |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A10H SDUCR/L-07 mit IK | 10 | 09 | 100 | 08 | ≥13 | DCG./DCM. 07.. |

| A12H SDUCR/L-07 mit IK | 12 | 11 | 100 | 10 | ≥16 | DCG./DCM. 07.. |

| A16M SDUCR/L-07 mit IK | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 07.. |

| A16M SDUCR/L-11 mit IK | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 11.. |

| A20P SDUCR/L-11 mit IK | 20 | 18 | 170 | 15 | ≥25 | DCG./DCM. 11.. |

| A25R SDUCR/L-11 mit IK | 25 | 23 | 200 | 19,5 | ≥32 | DCG./DCM. 11.. |

| A32S SDUCR/L-11 mit IK | 32 | 30 | 250 | 24 | ≥40 | DCG./DCM. 11.. |

| Boring Bar | SDUCR/L |

| Cutting Angle | 93° |

| Insert | DC.. |

| Clamping | Screw Clamping |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| Art. Nr. | d | h | L | f | Dmin | Insert | Screw | Shim | Shim-Screw | |

| A10H SDUCR-07 with cooling holes | SM36093 | 10 | 09 | 100 | 08 | ≥13 | DCG./DCM. 07.. | SSV M2,5x6 | - | - |

| A10H SDUCL-07 with cooling holes | SM36109 | 10 | 09 | 100 | 08 | ≥13 | DCG./DCM. 07.. | SSV M2,5x6 | - | - |

| A12H SDUCR-07 with cooling holes | SM36116 | 12 | 11 | 100 | 10 | ≥16 | DCG./DCM. 07.. | SSV M2,5x6 | - | - |

| A12H SDUCL-07 with cooling holes | SM36123 | 12 | 11 | 100 | 10 | ≥16 | DCG./DCM. 07.. | SSV M2,5x6 | - | - |

| A16M SDUCR-07 with cooling holes | SM36130 | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 07.. | SSV M2,5x6 | - | - |

| A16M SDUCL-07 with cooling holes | SM36147 | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 07.. | SSV M2,5x6 | - | - |

| A16M SDUCR-11 with cooling holes | SM36154 | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 11.. | SSV M3,5x10 | - | - |

| A16M SDUCL-11 with cooling holes | SM36161 | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 11.. | SSV M3,5x10 | - | - |

| A20P SDUCR-11 with cooling holes | SM36178 | 20 | 18 | 170 | 15 | ≥25 | DCG./DCM. 11.. | SSV M3,5x10 | - | - |

| A20P SDUCL-11 with cooling holes | SM36185 | 20 | 18 | 170 | 15 | ≥25 | DCG./DCM. 11.. | SSV M3,5x10 | - | - |

| A25R SDUCR-11 with cooling holes | SM36192 | 25 | 23 | 200 | 19,5 | ≥32 | DCG./DCM. 11.. | SSV M3,5x10 | BAX DC11 | SBV5 M5x0,5 A3,5x9 |

| A25R SDUCL-11 with cooling holes | SM36208 | 25 | 23 | 200 | 19,5 | ≥32 | DCG./DCM. 11.. | SSV M3,5x10 | BAX DC11 | SBV5 M5x0,5 A3,5x9 |

| A32S SDUCR-11 with cooling holes | SM36215 | 32 | 30 | 250 | 24 | ≥40 | DCG./DCM. 11.. | SSV M3,5x14 | BAX DC11 | SBV M5x0,5 A3,5x11 |

| A32S SDUCL-11 with cooling holes | SM36222 | 32 | 30 | 250 | 24 | ≥40 | DCG./DCM. 11.. | SSV M3,5x14 | BAX DC11 | SBV M5x0,5 A3,5x11 |

| Boring Bar | SDUCR/L |

| Cutting Angle | 93° |

| Insert | DC.. |

| Clamping | Screw Clamping |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A10H SDUCR/L-07 mit IK | 10 | 09 | 100 | 08 | ≥13 | DCG./DCM. 07.. |

| A12H SDUCR/L-07 mit IK | 12 | 11 | 100 | 10 | ≥16 | DCG./DCM. 07.. |

| A16M SDUCR/L-07 mit IK | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 07.. |

| A16M SDUCR/L-11 mit IK | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 11.. |

| A20P SDUCR/L-11 mit IK | 20 | 18 | 170 | 15 | ≥25 | DCG./DCM. 11.. |

| A25R SDUCR/L-11 mit IK | 25 | 23 | 200 | 19,5 | ≥32 | DCG./DCM. 11.. |

| A32S SDUCR/L-11 mit IK | 32 | 30 | 250 | 24 | ≥40 | DCG./DCM. 11.. |

Compatible products

Indexable insert - DCGT ... -ALZ RT100

| Shape | DCGT |

| Workpiece Material | NF-Materials |

| Grade | RT100: Uncoated K10-K15 carbide for ALU and plastics |

| Packaging unit | 10 Pc. |

| r | L | I.C | S | d | |

| DCGT 070201-ALZ RT100 | 0,1 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070202-ALZ RT100 | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070204-ALZ RT100 | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070208-ALZ RT100 | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 11T302-ALZ RT100 | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCGT 11T304-ALZ RT100 | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCGT 11T308-ALZ RT100 | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -HM RT250

| Shape | DCMT |

| Processing | Medium |

| Worpiece Material | Steel |

| Grade | RT250: CVD-coated P25-TIN hard metal for general steel processing |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070202-HM RT250 | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070204-HM RT250 | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070208-HM RT250 | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T302-HM RT250 | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T304-HM RT250 | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-HM RT250 | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -HM RT300

| Shape | DCMT |

| Processing | Medium |

| Workpiece Material | Steel and Stainless Steel |

| Grade | RT300: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070202-HM RT300 | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070204-HM RT300 | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070208-HM RT300 | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T302-HM RT300 | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T304-HM RT300 | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-HM RT300 | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable CBN-Insert - DCGW ...-2N RTC20T

| Shape | DCGW |

| Scope of application | Hard turning |

| Cutting edges | 2 |

| Grade | RTC20T : TIN-coated CBN for full to lightly interrupted cuts in hardened steels |

| Packaging unit | 2 Pc |

| I.C. | S | r | d | L | |

| DCGW 070204-2N RTC20T | 6,35 | 2,38 | 0,4 | 2,8 | 2,2 |

| DCGW 070208-2N RTC20T | 6,35 | 2,38 | 0,8 | 2,8 | 2,2 |

| DCGW 11T302-2N RTC20T | 9,525 | 3,97 | 0,2 | 4,4 | 2,2 |

| DCGW 11T304-2N RTC20T | 9,525 | 3,97 | 0,4 | 4,4 | 2,2 |

| DCGW 11T308-2N RTC20T | 9,525 | 3,97 | 0,8 | 4,4 | 2,2 |

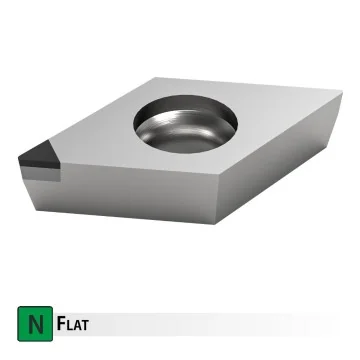

PCD-Insert - DCGW ...-1N RTD10

| Shape | DCGW |

| Processing | High Speed Alu Turning |

| Workpiece Material | Aluminum, NF-Materials |

| Grade | RTD10: Polycrystalline diamond for high-speed machining of aluminum up to 12% Si, non-ferrous metals and plastic |

| Packaging unit | 2 Pc. |

PCD = Polycrystalline diamond (PCD) is a synthetically produced, extremely hard, intergrown mass of randomly oriented diamond particles in a metal matrix.

| r | L | I.C | S | d | |

| DCGW 070202-1N RTD10 | 0,2 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGW 070204-1N RTD10 | 0,4 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGW 11T302-1N RTD10 | 0,2 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGW 11T304-1N RTD10 | 0,4 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGW 11T308-1N RTD10 | 0,8 | 2,5 | 9,525 | 3,97 | 4,4 |

PCD-Insert - DCGT ...-1N RTD10

| Shape | DCGT |

| Processing | High Speed Alu Turning |

| Workpiece Material | Aluminum, NF-Materials |

| Grade | RTD10: Polycrystalline diamond for high-speed machining of aluminum up to 12% Si, non-ferrous metals and plastic |

| Packaging unit | 2 Pc. |

PCD = Polycrystalline diamond (PCD) is a synthetically produced, extremely hard, intergrown mass of randomly oriented diamond particles in a metal matrix.

| r | L | I.C | S | d | |

| DCGT 070202-1N RTD10 | 0,2 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGT 070204-1N RTD10 | 0,4 | 2,5 | 6,35 | 2,38 | 2,8 |

| DCGT 11T302-1N RTD10 | 0,2 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGT 11T304-1N RTD10 | 0,4 | 2,5 | 9,525 | 3,97 | 4,4 |

| DCGT 11T308-1N RTD10 | 0,8 | 2,5 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -PM RT250+

| Shape | DCMT |

| Processing | Medium |

| Workpiece Material | Steel |

| Grade | RT250+: CVD-coated 2-color coated P20-P30 carbide for steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070204-PM RT250+ | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T304-PM RT250+ | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-PM RT250+ | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -PR RT250+

| Shape | DCMT |

| Processing | Roughing |

| Workpiece Material | Steel |

| Grade | RT250+: CVD-coated 2-color coated P20-P30 carbide for steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 11T304-PR RT250+ | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-PR RT250+ | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCGT ... -ALM RT105C

| Shape | DCGT |

| Processing | Medium and Finish |

| Workpiece Material | NF-Materials, Stainless Steel and Special Materials |

| Grade | RT105C: PVD-TiALN coated M10-M20 carbide for ALU / stainless steel |

| Packaging unit | 10 Pc. |

| r | L | I.C | S | d | |

| DCGT 070202-ALM RT105C | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070204-ALM RT105C | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 070208-ALM RT105C | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCGT 11T302-ALM RT105C | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCGT 11T304-ALM RT105C | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCGT 11T308-ALM RT105C | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT ... -HF RT250X

| Shape | DCMT |

| Processing | Medium and finish |

| Workpiece Material | Steel and Stainless Steel |

| Grade | RT250X = PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 11T304-HF RT250X | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-HF RT250x | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT...-MF RT255M

| Plate Shape | DCMT |

| Processing | Finishing |

| Material | Stainless Steel |

| Coating | RT255M: PVD coated M20-M30 carbide, first choice for stainless steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070202-MF RT255 | 0,2 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070204-MF RT255 | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T302-MF RT255 | 0,2 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T304-MF RT255 | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-MF RT255 | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

Indexable insert - DCMT...-MM RT255M

| Plate Shape | DCMT |

| Processing | Medium |

| Material | Stainless Steel |

| Coating | RT255M: PVD coated M20-M30 carbide, good choice for stainless steel |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | |

| DCMT 070204-MM RT255M | 0,4 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 070208-MM RT255M | 0,8 | 7,8 | 6,35 | 2,38 | 2,8 |

| DCMT 11T304-MM RT255M | 0,4 | 11,6 | 9,525 | 3,97 | 4,4 |

| DCMT 11T308-MM RT255M | 0,8 | 11,6 | 9,525 | 3,97 | 4,4 |

16 other products in the same category:

Internal Tool Holder - STFCR/L (90°)

| Boring Bar | STFCR/L |

| Cutting Angle | 90° |

| Insert | TC.. |

| Main application | Longitudinal turning |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| S10K STFCR 11 | 10 | 9 | 125 | 10 | ≥13 | TCG./TCM. 11.. |

| S10K STFCL 11 | 10 | 9 | 125 | 10 | ≥13 | TCG./TCM. 11.. |

| S12K STFCR 11 | 12 | 11 | 125 | 10 | ≥17 | TCG./TCM. 11.. |

| S12K STFCL 11 | 12 | 11 | 125 | 10 | ≥17 | TCG./TCM. 11.. |

| S16P STFCR 11 | 16 | 15 | 170 | 13 | ≥21 | TCG./TCM. 11.. |

| S16P STFCL 11 | 16 | 15 | 170 | 13 | ≥21 | TCG./TCM. 11.. |

Internal Tool Holder - PSKNR/L (75°)

| Boring Bar | PSKNR/L |

| Cutting Angle | 75° |

| Insert | SN.. 1204 |

| Main application | Longitudinal turning |

| Clamping | Pin Lock |

| Cooling | Without Cooling Hole |

| Packaging unit | 1 Pc. |

| d | L | h | f | Dmin | |

| S25Q-PSKNR/L 12 | 25 | 180 | 23 | 17 | 32 |

| S25T-PSKNR/L 12 | 25 | 300 | 23 | 17 | 32 |

| S32R-PSKNR/L 12 | 32 | 200 | 30 | 22 | 44 |

| S32U-PSKNR/L 12 | 32 | 350 | 30 | 22 | 44 |

| S40S-PSKNR/L 12 | 40 | 250 | 37 | 27 | 54 |

| S40V-PSKNR/L 12 | 40 | 400 | 37 | 27 | 54 |

Sleeve

Packaging unit = 1 Pc.

| Ød | a | b | c | ØD | H | L | |

| SL1604 (For E04...Boring bars) | 4 | 5 | 6 | -- | 16 | 14 | 100 |

| SL1605 (For E05...Boring bars) | 5 | 5 | 8 | -- | 16 | 14 | 100 |

| SL1606 (For E06...Boring bars) | 6 | 5 | 6 | 6 | 16 | 14 | 100 |

Internal Tool Holder - PSKNR/L (75°) with cooling holes

| Boring Bar | PSKNR/L |

| Cutting Angle | 75° |

| Insert | SN.. 1204 |

| Main application | Longitudinal turning |

| Clamping | Pin Lock |

| Cooling | With Cooling Hole |

| Packaging unit | 1 Pc. |

| d | L | h | f | Dmin | |

| A25R-PSKNR/L 12 | 25 | 200 | 24 | 17 | 32 |

| A32S-PSKNR/L 12 | 32 | 250 | 31 | 22 | 44 |

Internal Tool Holder - SVUBR/L (93°)

| Boring Bar | SVUBR/L |

| Cutting Angle | 93° |

| Insert | VB.. |

| Main Application | Profiling |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| S16P SVUBR-11 | 16 | 15 | 170 | 13 | ≥21 | VBM. 1103.. |

| S16P SVUBL-11 | 16 | 15 | 170 | 13 | ≥21 | VBM. 1103.. |

| S20R SVUBR-11 | 20 | 18 | 200 | 15 | ≥25 | VBM. 1103.. |

| S20R SVUBL-11 | 20 | 18 | 200 | 15 | ≥25 | VBM. 1103.. |

| S25S SVUBR-16 | 25 | 23 | 250 | 19,5 | ≥32 | VBM. 1604.. |

| S25S SVUBL-16 | 25 | 23 | 250 | 19,5 | ≥32 | VBM. 1604.. |

| S32T SVUBR-16 | 32 | 30 | 300 | 24 | ≥40 | VBM. 1604.. |

| S32T SVUBL-16 | 32 | 30 | 300 | 24 | ≥40 | VBM. 1604.. |

| S40U SVUBR-16 | 40 | 37 | 350 | 30 | ≥50 | VBM. 1604.. |

| S40U SVUBL-16 | 40 | 37 | 350 | 30 | ≥50 | VBM. 1604.. |

Internal Tool Holder - TCLNR/L (95°) with clamping

| Boring Bar | TCLNR/L |

| Cutting Angle | 95° |

| Insert | CN.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Claw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

Particularly suitable for roughing due to stable claw clamping.

| d | h | L | f | Dmin | Insert | |

| S20R TCLNR-12 | 20 | 18 | 200 | 15 | ≥26 | CN.. 1204.. |

| S20R TCLNL-12 | 20 | 18 | 200 | 15 | ≥26 | CN.. 1204.. |

| S25S TCLNR-12 | 25 | 23 | 250 | 19,5 | ≥38 | CN.. 1204.. |

| S25S TCLNL-12 | 25 | 23 | 250 | 19,5 | ≥38 | CN.. 1204.. |

| S32T TCLNR-12 | 32 | 30 | 300 | 24 | ≥40 |

CN.. 1204.. |

| S32T TCLNL-12 | 32 | 30 | 300 | 24 | ≥40 | CN.. 1204.. |

| S40U TCLNR-12 | 40 | 37 | 350 | 30 | ≥50 | CN.. 1204.. |

| S40U TCLNL-12 | 40 | 37 | 350 | 30 | ≥50 | CN.. 1204.. |

| S40U TCLNR-16 | 40 | 37 | 350 | 30 | ≥44 | CN.. 1606.. |

| S40U TCLNL-16 | 40 | 37 | 350 | 30 | ≥44 | CN.. 1606.. |

| S50V TCLNR-12 | 50 | 47 | 400 | 38 | ≥63 | CN.. 1204.. |

| S50V TCLNL-12 | 50 | 47 | 400 | 38 | ≥63 | CN.. 1204.. |

Internal Tool Holder - SVJBR/L (93°)

| Boring Bar | SVJBR/L |

| Cutting Angle | 93° |

| Insert | VBMT 1604... |

| Main application | Profiling |

| Clamping | Screw Clamping |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | |

| S25S SVJBR-16-S | 25 | 23 | 250 | 19,5 | ≥32 |

| S25S SVJBL-16-S | 25 | 23 | 250 | 19,5 | ≥32 |

| S32T SVJBR-16 | 32 | 30 | 300 | 24 | ≥40 |

| S32T SVJBL-16 | 32 | 30 | 300 | 24 | ≥40 |

| S40U SVJBR-16 | 40 | 37 | 350 | 30 | ≥50 |

| S40U SVJBL-16 | 40 | 37 | 350 | 30 | ≥50 |

Internal Tool Holder - SDQCR/L (107,5°)

| Boring Bar | SDQCR/L |

| Cutting Angle | 107,5° |

| Insert | DC.. |

| Main application | Profiling |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| S12K SDQCR/L-07 | 12 | 11 | 125 | 10 | ≥16 | DCG./DCM. 07.. |

| S16P SDQCR/L-07 | 16 | 15 | 170 | 13 | ≥21 | DCG./DCM. 07.. |

| S16P SDQCR/L-11 |

16 | 15 | 170 | 13 | ≥21 | DCG./DCM. 11.. |

| S20R SDQCR/L-11 |

20 | 18 | 200 | 15 | ≥25 | DCG./DCM. 11.. |

| S25S SDQCR/L-11 |

25 | 23 | 250 | 19,5 | ≥32 | DCG./DCM. 11.. |

Internal Tool Holder - SVUCR/L (93°)

| Boring Bar | SVUCR/L |

| Cutting Angle | 93° |

| Insert | VC.. |

| Main application | Profile turning |

| Clamping | Screw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| S16P SVUCR/L-11 | 16 | 15 | 170 | 13 | ≥21 | VCM./VCG. 1103.. |

| S20R SVUCR/L-11 | 20 | 18 | 200 | 15 | ≥25 | VCM./VCG. 1103.. |

| S25S SVUCR/L-16 | 25 | 23 | 250 | 19,5 | ≥32 | VCM./VCG. 1604.. |

| S32T SVUCR/L-16 | 32 | 30 | 300 | 24 | ≥40 | VCM./VCG. 1604.. |

| S40U SVUCR/L-16 | 40 | 37 | 350 | 30 | ≥50 | VCM./VCG. 1604.. |

Internal Tool Holder - PCLNR/L (95°)

| Boring Bar | SPCLNR/L |

| Cutting Angle | 95° |

| Insert | CN.. |

| Main application | Longitudinal turning, Facing |

| Clamping | Pin Lock |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

| d | L | h | f | Dmin | |

| S25Q-PCLNR/L 12 | 25 | 180 | 23 | 17 | 32 |

| S25T-PCLNR/L 12 |

25 | 300 | 23 | 17 | 32 |

| S32R-PCLNR/L 12 |

32 | 200 | 30 | 22 | 44 |

| S32U-PCLNR/L 12 |

32 | 350 | 30 | 22 | 44 |

| S40S-PCLNR/L 12 |

40 | 250 | 37 | 27 | 54 |

| S40V-PCLNR/L 12 |

40 | 400 | 37 | 27 | 54 |

| S50S-PCLNR/L 12 |

50 | 250 | 47 | 35 | 63 |

| S50W-PCLNR/L 12 |

50 | 450 | 47 | 35 | 63 |

| S50S-PCLNR/L 19 |

50 | 250 | 47 | 35 | 63 |

| S50W-PCLNR/L 19 |

50 | 450 | 47 | 35 | 63 |

Internal Tool Holder - TDUNR/L (93°) with clamping

| Boring Bar | TDUNR/L |

| Cutting Angle | 93° |

| Insert | DN.. |

| Main application | Profiling |

| Clamping | Claw Clamping |

| Cooling | Without Cooling Holes |

| Packaging unit | 1 Pc. |

Particularly suitable for roughing due to stable claw clamping.

| d | h | L | f | Dmin | Insert | |

| S25S TDUNR-11 | 25 | 23 | 250 | 19,5 | ≥33 | DNM. 1104.. |

| S25S TDUNL-11 | 25 | 23 | 250 | 19,5 | ≥33 | DNM. 1104.. |

| S32T TDUNR-11 | 32 | 30 | 300 | 24 | ≥40 |

DNM. 1104.. |

| S32T TDUNL-11 | 32 | 30 | 300 | 24 | ≥40 | DNM. 1104.. |

| S25S TDUNR-15 | 25 | 23 | 250 | 19,5 | ≥39 | DNM. 1506.. |

| S25S TDUNL-15 | 25 | 23 | 250 | 19,5 | ≥39 | DNM. 1506.. |

| S32T TDUNR-15 | 32 | 30 | 300 | 24 | ≥40 | DNM. 1506.. |

| S32T TDUNL-15 | 32 | 30 | 300 | 24 | ≥40 | DNM. 1506.. |

| S40U TDUNR-15 | 40 | 37 | 350 | 30 | ≥50 | DNM. 1506.. |

| S40U TDUNL-15 | 40 | 37 | 350 | 30 | ≥50 | DNM. 1506.. |

Internal Tool Holder - SDQCR/L (107,5°) with cooling holes

| Boring Bar | SDQCR/L |

| Cutting Angle | 107,5° |

| Insert | DC.. |

| Main application | Profiling |

| Clamping | Screw Clamping |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

| d | h | L | f | Dmin | Insert | |

| A10H SDQCR/L-07 with cooling holes | 10 | 09 | 100 | 08 | ≥13 | DCG./DCM. 07.. |

| A12H SDQCR/L-07 with cooling holes | 12 | 11 | 100 | 10 | ≥16 | DCG./DCM. 07.. |

| A16M SDQCR/L-07 with cooling holes | 16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 07.. |

| A16M SDQCR/L-11 with cooling holes |

16 | 15 | 150 | 13 | ≥21 | DCG./DCM. 11.. |

| A20P SDQCR/L-11 with cooling holes |

20 | 18 | 170 | 15 | ≥25 | DCG./DCM. 11.. |

| A25R SDQCR/L-11 with cooling holes |

25 | 23 | 200 | 19,5 | ≥32 | DCG./DCM. 11.. |

| A32S SDQCR/L-11 with cooling holes | 32 | 30 | 250 | 24 | ≥40 | DCG./DCM. 11.. |

SMCR/L XC.. MULTI CUT

| Tool Typ | Multifunction Tool |

| Angle | 90° |

| Applications | Longitudinal turning - Facing- Drilling |

| Insert | XC.. |

| Packaging Unit | 1 Pc. |

| d | d1 | d2 | L1 | L2 | L3 | F | |

| SMCR/L 10x2,5 XC..05... | 10 | 12 | 16 | 25 | 32 | 42 | 5 |

| SMCR/L 12x2,5 XC..06... |

12 | 16 | 20 | 30 | 40 | 45 | 6 |

| SMCR/L 16x2,5 XC..08... |

16 | 20 | 25 | 40 | 53 | 50 | 8 |

| SMCR/L 20x2,5 XC..10... |

20 | 25 | 34 | 50 | 66 | 55 | 10 |

| SMCR/L 25x2,5 XC..13.. |

25 | 25 | 34 | 62,5 | 80 | 55 | 12,5 |

| SMCR/L 32x2,5 XC..17... |

32 | 32 |

44 |

80 | 95 |

60 |

16 |

Solid Carbide Internal Tool Holder - E-SDQCR/L (107,5°) with cooling holes

| Boring Bar | E-SDQCR/L |

| Setting Angle | 107,5° |

| Insert | DC.. |

| Main application | Profile turning |

| Clamping | Screw Clamp |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

Solid carbide boring bar

Solid carbide tool carriers increase stability considerably.

The carbide boring bar allows a projection length of up to 6xD by reducing vibrations.

Precision and surface quality are also improved.

| d | L | f | D/min | |

| E10M SDQCR/L-07 with cooling holes | 10 | 150 | 8 | ≥13 |

| E12Q SDQCR/L-07 with cooling holes | 12 | 180 | 10 | ≥16 |

| E16R SDQCR/L-11 with cooling holes | 16 | 200 | 13 | ≥21 |

Solid Carbide Internal Tool Holder - E...-SCLCR/L-03

| Boring Bar | E... SCLCR/L |

| Cutting Angle | 95° |

| Insert | CCGT 03... |

| Clamping | Screw Clamp |

| Cooling | With Cooling Holes |

| Packaging unit | 1 Pc. |

Solid Carbide Internal Tool Holder

| Ød | L | S | Dmin | |

| E04J-SCLCR-03 (CCGT 030102L) | 4 | 90 | 2,5 | 5 |

| E04J-SCLCL-03 (CCGT 030102R) | 4 | 90 | 2,5 | 5 |

| E05J-SCLCR-03 (CCGT 030102L) | 5 | 100 | 3 | 6 |

| E05J-SCLCL-03 (CCGT 030102R) | 5 | 100 | 3 | 6 |

| E06J-SCLCL-03 (CCGT 030202R) | 6 | 110 | 3,5 | 7 |

| E06J-SCLCL-03 (CCGT 030202R) | 6 | 110 | 3,5 | 7 |

Internal Tool Holder - PDUNR/L (93°)

| Boring Bar | PDUNR/L |

| Cutting Angle | 93° |

| Insert | DN.. |

| Main application | Profiling |

| Clamping | Pin Lock |

| Cooling | Without Cooling Hole |

| Packaging unit | 1 Pc. |

| d | L | h | f | Dmin | |

| S20Q-PDUNR/L 11 | 20 | 180 | 18 | 13 | 25 |

| S20S-PDUNR/L 11 |

20 | 250 | 18 | 13 | 25 |

| S25Q-PDUNR/L 11 |

25 | 180 | 23 | 17 | 32 |

| S25T-PDUNR/L 11 |

25 | 300 | 23 | 17 | 32 |

| S32R-PDUNR/L 11 |

32 | 200 | 30 | 22 | 40 |

| S32U-PDUNR/L 11 |

32 | 350 | 30 | 22 | 40 |

| S32R-PDUNR/L 15 |

32 | 200 | 30 | 22 | 40 |

| S32U-PDUNR/L 15 |

32 | 350 | 30 | 22 | 40 |

| S40S-PDUNR/L 15 |

40 | 250 | 37 | 27 | 50 |

| S40V-PDUNR/L 15 |

40 | 400 | 37 | 27 | 50 |

| S50V-PDUNR/L 15 | 50 | 400 | 47 | 32 | 60 |