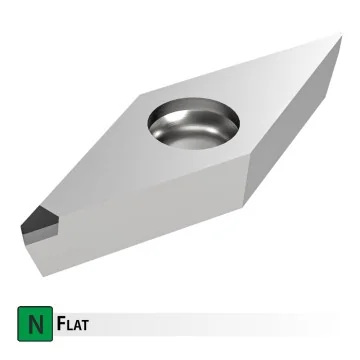

Indexable insert - VCGT ...-ALZ RT100

| Shape | VCGT |

| Workpiece Material | NF-Materials |

| Cutting conditions | Continuous |

| Grade | RT100: Uncoated K10-K15 carbide for ALU and plastics |

| Packaging unit | 10 Pc. |

| r | L | I.C | S | d | |

| VCGT 110302-ALZ RT100 | 0,2 | 11 | 6,35 | 3,18 | 2,8 |

| VCGT 110304-ALZ RT100 | 0,4 | 11 | 6,35 | 3,18 | 2,8 |

| VCGT 160402-ALZ RT100 | 0,2 | 16,6 | 9,525 | 4,76 | 4,4 |

| VCGT 160404-ALZ RT100 | 0,4 | 16,6 | 9,525 | 4,76 | 4,4 |

| VCGT 160408-ALZ RT100 | 0,8 | 16,6 | 9,525 | 4,76 | 4,4 |

| VCGT 160412-ALZ RT100 | 1,2 | 16,6 | 9,525 | 4,76 | 4,4 |

| VCGT 220530-ALZ RT100 | 3 | 22 | 12,7 | 5,56 | 5,5 |