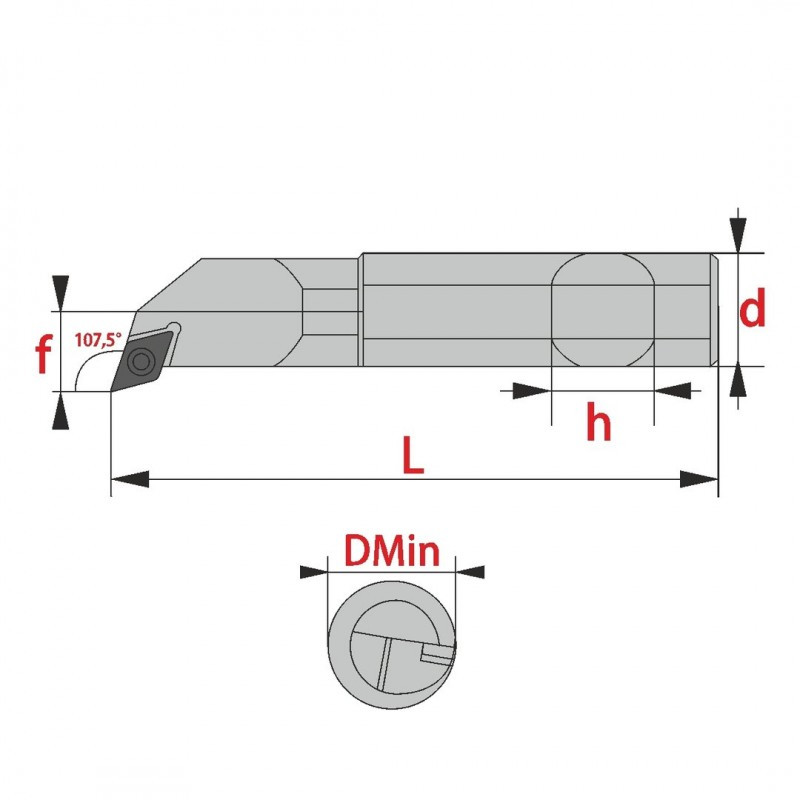

End-Mill-Set 12 to 20mm APKT1003...

Packaging unit = 1 Pc.

Consisting of 3 End mills Typ APKT 1003..... for Weldon Chucks.

- 1 x Diameter 12mm / Z = 1 / L = 120mm

- 1 x Diameter 16mm / Z = 2 / L = 120mm with cooling holes.

- 1 x Diameter 20mm / Z = 3 / L = 120mm with cooling holes.

For all inserts APKT 1003-ISO.