IPM5x13

| Screw Type | Torx |

| Head Size | T20 |

| Torque | 6,7 Nm |

| Packaging unit | 1 piece |

TURNING INSERTS

PARTING AND GROOVING

TIP DRILLS

INDEXEABLE INSERT DRILLS

SOLID CARBIDE DRILLS

COUNTERSINK & DEBURRING TOOLS

COMPATIBLE INSERTS

SPARE PARTS & ACCESSORIES

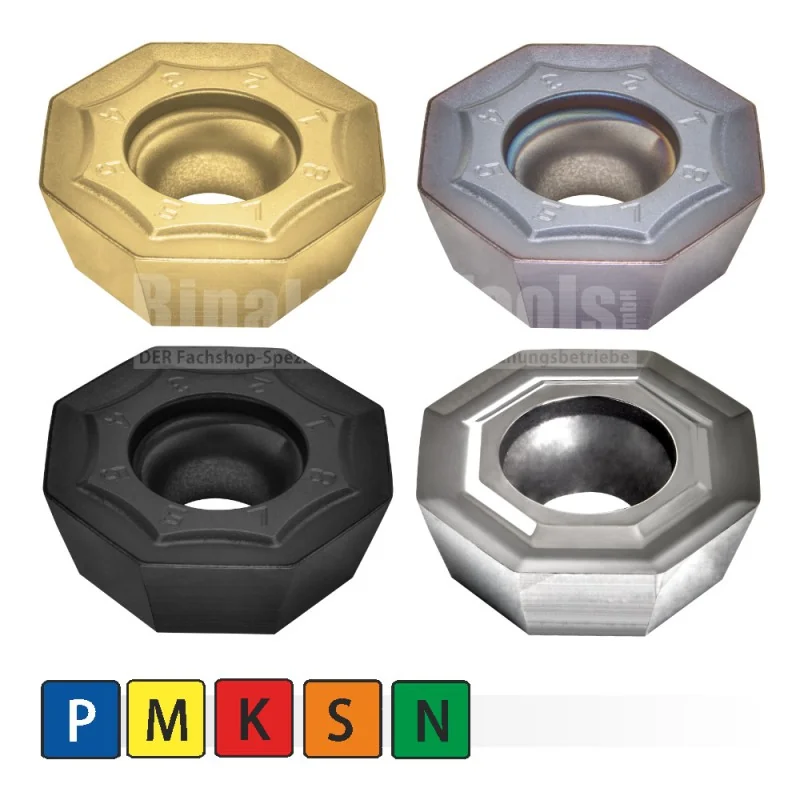

| Shape | SEET |

Grades |

RT100: Uncoated K10-K15 carbide for aluminum and plastics |

| RT150K: CVD-coated K10-K20 carbide for cast iron machining | |

| RT250X: PVD-Multilayer Beschichtetes P10-P30 und M10-M30 Hartmetall für die Universelle Anwendung in Stahl und Edelstahl | |

| RT305H: High-Performance PVD coating for efficient use in stainless steel and superalloy. | |

| Packagig Unit | 10 pc. |

| L | I.C. | S | d | r | Scope of application | |

| ODHT 060508-M RT305H | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Stainless Steel & Super alloys |

| ODHT 060508-M RT250X | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Steel & Stainless Steel |

| ODHT 060508-M RT150K | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Cast Iron |

| ODHT 060508-ALZ RT100 | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | ALU / Plastic / NE-Materials |

| Shape | SEET |

Grades |

RT100: Uncoated K10-K15 carbide for aluminum and plastics |

| RT150K: CVD-coated K10-K20 carbide for cast iron machining | |

| RT250X: PVD-Multilayer Beschichtetes P10-P30 und M10-M30 Hartmetall für die Universelle Anwendung in Stahl und Edelstahl | |

| RT305H: High-Performance PVD coating for efficient use in stainless steel and superalloy. | |

| Packagig Unit | 10 pc. |

| Item Nr. | L | I.C. | S | d | r | Scope of application | |

| ODHT 060508-M RT305H | 2651332 | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Stainless Steel & Super alloys |

| ODHT 060508-M RT250X | 2651333 | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Steel & Stainless Steel |

| ODHT 060508-M RT150K | 2651334 | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Cast Iron |

| ODHT 060508-ALZ RT100 | 2651331 | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | ALU / Plastic / NE-Materials |

| Steel | Stainless Steel | Cast Iron | NF-Materials | Special Materials | ||||||

| Vc (m/min) | fz (mm) | Vc (m/min) | fz (mm) | Vc (m/min) | fz (mm) | Vc (m/min) | fz (mm) | Vc (m/min) | fz (mm) | |

| ODHT 060508-M RT305H | 130-250 | 0,18-0,25 | 80-150 | 0,14-0,18 | - | - | - | - | 30-80 | 0,14-0,18 |

| ODHT 060508-M RT250X | 100-260 | 0,18-0,25 | 100-150 | 0,14-0,18 | - | - | - | - | - | - |

| ODHT 060508-M RT150K | - | - | - | - | 150-360 | 0,2-0,28 | - | - | - | - |

| ODHT 060508-ALZ RT100 | - | - | - | - | - | - | 200-900 | 0,15-0,21 | - | - |

| Shape | SEET |

Grades |

RT100: Uncoated K10-K15 carbide for aluminum and plastics |

| RT150K: CVD-coated K10-K20 carbide for cast iron machining | |

| RT250X: PVD-Multilayer Beschichtetes P10-P30 und M10-M30 Hartmetall für die Universelle Anwendung in Stahl und Edelstahl | |

| RT305H: High-Performance PVD coating for efficient use in stainless steel and superalloy. | |

| Packagig Unit | 10 pc. |

| L | I.C. | S | d | r | Scope of application | |

| ODHT 060508-M RT305H | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Stainless Steel & Super alloys |

| ODHT 060508-M RT250X | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Steel & Stainless Steel |

| ODHT 060508-M RT150K | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | Cast Iron |

| ODHT 060508-ALZ RT100 | 6,50 | 15,875 | 5,56 | 5,4 | 0,8 | ALU / Plastic / NE-Materials |

| Screw Type | Torx |

| Head Size | T20 |

| Torque | 6,7 Nm |

| Packaging unit | 1 piece |

| Mill type | Face Mill |

| Platte | ODHT 06... |

| Packaging unit | 1 piece |

| D | D1 | d | L | ap max | Z | Version | |

| MK45 OD06 D50 A22 Z04-H mit IK | 50 | 60 | 22 | 40 | 4 | 4 | A |

| MK45 OD06 D63 A22 Z05-H mit IK | 63 | 73 | 22 | 40 | 4 | 5 | A |

| MK45 OD06 D80 A27 Z06-H mit IK | 80 | 90 | 27 | 50 | 4 | 6 | A |

| MK45 OD06 D100 A32 Z07-H mit IK | 100 | 110 | 27 | 50 | 4 | 7 | A |

| MK45 OD06 D125 B40 Z08 | 125 | 135 | 32 | 63 | 4 | 8 | B |

| Shape | RDKW |

| Processing | Medium |

| Workpiece Material | Steel and Cast Iron |

| Grade | RT300: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel |

| Packaging unit | 10 Pc. |

| I.C | S | d | |

| RDKW 0702MO RT300 | 7 | 2,38 | 2,7 |

| RDKW 1003MO RT300 | 10 | 3,18 | 3,9 |

| RDKW 12T3MO RT300 | 12 | 3,97 | 3,9 |

| RDKW 1604MO RT300 | 16 | 4,76 | 5,2 |

| Shape | RDMT |

| Processing | Medium |

| Workpiece Material | Steel, Stainless Steel, Cast Iron, Special Alloys, Hardened Steel |

| Grade | RT305H: PVD-coated High-Performance grade for a wide range of usage |

| Packaging unit | 10 Pc. |

| I.C. | S | d | |

| RDMT 10T3MO-M RT305H | 10 | 3,97 | 4,1 |

| RDMT 1204MO-M RT305H | 12 | 4,76 | 4,1 |

| Grooving Insert | RT22R/L RT305 |

| Workpiece Materials | Steel and Stainless Steel |

| Grooving system | RT-System |

| Grade | RT305 = PVD grade M20-M30 for stainless steel with the most modern coating |

| Packaging unit | 5 Pc. |

| W±0,025 | r | La max | øI.C | S | |

| RT22R100R RT305 | 1 | 0,5 | 2 | 12,7 | 4,76 |

| RT22L100R RT305 | 1 | 0,5 | 2 | 12,7 | 4,76 |

| RT22R150R RT305 | 1,5 | 0,75 | 3,5 | 12,7 | 4,76 |

| RT22L150R RT305 | 1,5 | 0,75 | 3,5 | 12,7 | 4,76 |

| RT22R170R RT305 | 1,7 | 0,85 | 3,5 | 12,7 | 4,76 |

| RT22R200R RT305 | 2 | 1 | 3,5 | 12,7 | 4,76 |

| RT22L200R RT305 | 2 | 1 | 3,5 | 12,7 | 4,76 |

| RT22R250R RT305 | 2,5 | 1,25 | 4 | 12,7 | 4,76 |

| RT22L250R RT305 | 2,5 | 1,25 | 4 | 12,7 | 4,76 |

| RT22R300R RT305 | 3 | 1,5 | 4 | 12,7 | 4,76 |

| RT22L300R RT305 | 3 | 1,5 | 4 | 12,7 | 4,76 |

| RT22R320R RT305 | 3,2 | 1,6 | 4 | 12,7 | 4,76 |

| RT22R400R RT305 | 4 | 2 | 5 | 12,7 | 4,76 |

| RT22L400R RT305 | 4 | 2 | 5 | 12,7 | 4,76 |

| Shape | LNMX |

| Processing | High Feed |

| Workpiece Material | Steel and Stainless Steel |

| Grade |

RT300: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel |

|

RT330: PVD-coated P15-P25 and M10-M25 with additional TiN-coating for improved wear-detection |

|

| Packaging unit | 10 Pc. |

.

| L | apmax | W | S | r | |

| LNMX 0303-MU RT300 | 11,86 | 1,00 | 6 | 4,29 | 1,20 |

| LNMX 0303-MU RT330 New! | 11,86 | 1,00 | 6 | 4,29 | 1,20 |

| Shape | SDMT |

| Processing | High Feed |

| Workpiece Material | Steel, Stainless Steel and Special Alloys |

|

Grade

|

RT253: CVD-coated M20–M35 carbide grade for roughing operations in stainless steel |

|

RT250X: PVD multilayer-coated P10–P30 and M10–M30 carbide grade for universal applications in steel and stainless steel |

|

|

RT300: PVD-coated P15–P25 and M10–M25 carbide grade for universal applications in steel and stainless steel |

|

|

RT820S: CVD-coated S10–S20 / M15–M35 high-performance milling grade for difficult-to-machine materials such as special alloys (titanium, Inconel, Hastelloy, and stainless steels such as 1.4571) |

|

| Packaging Unit | 10 PC |

| L | I.C | S | d | r | |

| SDMT 09T312–NM RT250X | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT253 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–PM RT300 | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 09T312–NM RT820S | 9,525 | 9,525 | 3,97 | 4 | 1,2 |

| SDMT 120412–NM RT250X | 12,7 | 12,7 | 4,76 | 4,4 | 1,2 |

| SDMT 120412–PM RT300 | 12,7 | 12,7 | 4,76 | 4,4 | 1,2 |

PLEASE NOTE!!

Holder MK90....-K for indexable insert VPGT ...-K (corner radius indexable insert up to 3.2 mm)

Holder MK90....-G for indexable insert VPGT ...-G (corner radius indexable insert from 4 mm)

| Inserts K | r | L | I.C. | S | d |

| VPGT 220502-K-ALZ RT100 | 0,2 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220505-K-ALZ RT100 | 0,5 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220508-K-ALZ RT100 | 0,8 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220510-K-ALZ RT100 |

1,0 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220515-K-ALZ RT100 | 1,5 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220520-K-ALZ RT100 |

2,0 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220525-K-ALZ RT100 | 2,5 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220530-K-ALZ RT100 | 3,0 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220532-K-ALZ RT100 | 3,2 | 12 | 12,70 | 5,56 | 5,50 |

| Inserts G | r | L | I.C. | S | d |

| VPGT 220540-G-ALZ RT100 | 4,0 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220550-G-ALZ RT100 | 5,0 | 12 | 12,70 | 5,56 | 5,50 |

| VPGT 220560-G-ALZ RT100 | 6,0 | 12 | 12,70 | 5,56 | 5,50 |

Packaging unit = 10 Pc.

| Shape | ONHU |

| Workpiece Materials |

RT250X: Steel and Stainless Steel RT150K: Cast Iron |

| Grades |

RT250X: PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel RT150K: CVD-coated K10-K20 carbide for rough cast machining |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | d | Scope of Application | |

| ONHU 060408-GM RT250X | 0,8 | 6,15 | 15,8 | 5,54 | 6,02 | Steel & Stainless Steel |

| ONHU 060408-GM RT150K | 0,8 | 6,15 | 15,8 | 5,54 | 6,02 | Cast Iron |

| Shape | RDMW |

| Processing | Medium |

| Workpiece Material | Steel, Cast Iron, Hardened Steel |

| Grade | RT305H: PVD-coated High-Performance grade for a wide range of usage |

| Packaging unit | 10 Pc. |

| I.C. | S | d | |

| RDMW 10T3MO-H RT305H | 10 | 3,97 | 4,1 |

| RDMW 1204MO-H RT305H | 12 | 4,76 | 4,1 |

| Shape | RDKW |

| Processing | Medium |

| Workpiece Material | Hard Materials |

| Grade | RT105H: PVD-TiALN coated M10-M20 carbide for hard materials |

| Packaging unit | 10 Pc. |

| I.C | S | d | |

| RDKW 0702MO RT105H HART | 7 | 2,38 | 2,7 |

| RDKW 1003MO RT105H HART | 10 | 3,18 | 3,9 |

| RDKW 10T3MO RT105H HART | 10 | 3,97 | 4,4 |

| RDKW 12T3MO RT105H HART | 12 | 3,97 | 3,9 |

| RDKW 1204MO RT105H HART | 12 | 4,76 | 4,4 |

| RDKW 1604MO RT105H HART | 16 | 4,76 | 5,2 |

| Shape | SPMR |

| Processing | Medium |

| Workpiece Material | Steel |

| Grade | RT250: CVD-coated P25-TIN hard metal for general steel processing |

| Packaging unit | 10 Pc. |

| r | L | I.C. | S | |

| SPMR 120308-PM RT250 | 0,8 | 12,7 | 12,7 | 3,18 |

| Shape | LNKT |

| Workpiece Material | Cast Iron |

| Grade | RT150K: CVD-coated K10-K20 carbide for cast machining |

| Packaging unit | 10 Pc. |

| L | S | W | r | |

| LNKT 080408-GM RT150K | 8,75 | 4,45 | 8,75 | 0,8 |

| LNKT 120608-GM RT150K | 12,7 | 6,75 | 12,7 | 0,8 |

| LNKT 160708-GM RT150K | 16,05 | 7,35 | 16,05 | 0,8 |

| Shape | SNHX |

| Workpiece Material | Steel and Stainless Steel |

| Grade | RT302: PVD-coated carbide grade for P15-P30 & M25-M40, suitable for medium to rough machining of stainless steel and steel (milling). |

| Packaging unit | 10 Pc. |

| d | L | I.C. | S | |

| SNHX 1202 RT302 | 5 | 12,7 | 12,7 | 2,3 |

| SNHX 1203 RT302 | 5 | 12,7 | 12,7 | 3 |

| SNHX 12T3 RT302 | 5 | 12,7 | 12,7 | 3,5 |

| Grooving Insert | RT16R/L RT305 |

| Workpiece Materials | Steel and Stainless Steel |

| Grooving system | RT-System |

| Grade | RT305 = PVD grade M20-M30 for stainless steel with the most modern coating |

| Packaging unit | 5 Pc. |

| W±0,025 | r | La max | øI.C | S | |

| RT16R100R RT305 | 1 | 0,5 | 2 | 9,525 | 3,18 |

| RT16R120R RT305 | 1,2 | 0,6 | 2 | 9,525 | 3,18 |

| RT16R150R RT305 | 1,5 | 0,75 | 2 | 9,525 | 3,18 |

| RT16R200R RT305 | 2 | 1 | 2,5 | 9,525 | 3,18 |

| RT16L200R RT305 | 2 | 1 | 2,5 | 9,525 | 3,18 |

| RT16R250R RT305 | 2,5 | 1,25 | 2,5 | 9,525 | 3,18 |

| RT16L280R RT305 | 2,8 | 1,4 | 2,5 | 9,525 | 3,18 |

| RT16R300R RT305 | 3 | 1,5 | 2,5 | 9,525 | 3,18 |

| RT16L300R RT305 | 3 | 1,5 | 2,5 | 9,525 | 3,18 |

| Shape | APKT |

| Workpiece Materials |

RT250X: Steel and Stainless Steel RT250K: Cast Iron |

| Grades |

RT250X = PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel RT250K = CVD-coated K25 carbide for rough cast machining |

| Packaging unit | 10 Pc. |

| L | d | s | d1 | r | |

| APKT 070204-PF RT250X | 7,28 | 4,34 | 2,38 | 2 | 0,4 |

| APKT 070204-PF RT250K | 7,28 | 4,34 | 2,38 | 2 | 0,4 |

Packaging unit = 10 Pc.

Scope of application: Steel und Stainless Steel

RT250X = PVD multilayer coated P10-P30 and M10-M30 carbide for universal use in steel and stainless steel

| L | S | W | r | |

| LNKT 080408-GM RT250X | 8,75 | 4,45 | 8,75 | 0,8 |

| LNKT 120608-GM RT250X | 12,7 | 6,75 | 12,7 | 0,8 |

| LNKT 160708-GM RT250X | 16,05 | 7,35 | 16,05 | 0,8 |

| Shape | APKT |

|

Grades |

RT400+: CVD-coated P30-P40 carbide for milling in steel |

| RT330: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel | |

| RT300: PVD-coated P15-P25 and M10-M25 for universal use in steel and stainless steel | |

| RT100: Uncoated K10-K15 carbide for ALU and plastics | |

| Packaging unit | 10 Pc. |

| L | d | s | d1 | r | |

| APKT 1604PDSR-30 RT400+ | 16,50 | 9,54 | 4,76 | 4,4 | 0,8 |

| APKT 1604PDSR-30 RT330 | 16,50 | 9,54 | 4,76 | 4,4 | 0,8 |

| APKT 1604PDTR RT300 | 16,50 | 9,54 | 4,76 | 4,4 | 0,95 |

| APKT 160424PDTR RT300 | 16,50 | 9,54 | 4,76 | 4,4 | 2,4 |

| APKT 1604-ALZ RT100 | 16,50 | 9,54 | 4,76 | 4,4 | 0,4 |

| APKT 160408-AL RT100 | 16,50 | 9,54 | 4,76 | 4,4 | 0,8 |